When operating a 3D printer, you're likely releasing harmful emissions that can cause eye irritation, lung problems, nausea, and headaches, making a well-designed exhaust system vital to maintaining a safe and healthy printing environment. To mitigate these risks, you'll need to select a vent system based on your printer's size and type, along with considering ventilation strategies like enclosures, fume hoods, and air purifiers. Proper filtration, such as HEPA filters and activated carbon, is also crucial. By optimizing your ventilation system, you can greatly reduce health risks and improve indoor air quality. Now, explore how to create a safe printing environment that meets your specific needs.

Understanding 3D Printer Emissions

Frequently, when you fire up your 3D printer, you're releasing harmful emissions into the air, whether you're working with resin or filament. These emissions can be detrimental to your health, releasing volatile organic compounds (VOCs) and particulates that can cause eye irritation, lung problems, nausea, and headaches.

The risks associated with 3D printer emissions aren't to be taken lightly, and daily exposure can lead to long-term health consequences. It's important to understand that both resin and filament printers require effective ventilation systems to minimize health risks. A fume hood or proper ventilation system is vital to reduce the risks associated with 3D printer emissions.

Without proper ventilation, you're putting your health at risk. It's crucial to prioritize your health and take the necessary steps to ensure a safe working environment. By understanding the emissions released by your 3D printer, you can take the necessary precautions to protect yourself and minimize the health risks associated with 3D printing.

Ventilation Strategies for Safety

To safeguard your health and create a safe printing environment, you need to implement effective ventilation strategies that can efficiently remove harmful emissions from your 3D printing process. One approach is to enclose your resin printer in a dedicated room with a ventilation system, which can greatly improve air quality and reduce exposure to particulates and VOCs.

Another strategy is to use an inline fan to exhaust fumes directly outdoors, maintaining a healthy working environment. Combining ventilation methods, such as utilizing grow tents with flexible ducts and air filters, can also effectively mitigate harmful emissions.

Moreover, consider investing in a fume extractor, specifically designed for 3D printing, to capture and remove particles and fumes. By implementing these ventilation strategies, you can minimize the risks associated with 3D printing emissions and establish a safe and healthy printing environment.

Choosing the Right Vent System

When selecting a vent system for your 3D printer, consider the size and type of your printer to make sure you choose an exhaust system that meets your specific ventilation needs.

You'll want to evaluate your ventilation needs based on the printing materials you use, such as resin or filaments, and how frequently you print. A compatible exhaust system should be able to handle the harmful fumes and particles emitted by your printer.

Look for systems with powerful fans and effective filtration, such as HEPA filters, to remove airborne pollutants. Moreover, consider investing in an air purifier to further improve your printer enclosure ventilation.

It's crucial to make sure the exhaust system is compatible with your printer model and can be easily integrated into your setup. Don't hesitate to seek advice from experts or refer to user reviews to select a reliable and efficient exhaust system for your 3D printer.

Effective Fume Extraction Methods

Three effective fume extraction methods for your 3D printer are fume hoods, enclosures, and air purifiers, each designed to capture and remove harmful emissions from your printing environment.

When selecting a fume extraction method, consider the type of printer you have, the size of your printing area, and the level of air purification you need.

Fume hoods, for instance, are ideal for small printing areas and can be easily installed above your printer. Enclosures, on the other hand, offer a more thorough solution by surrounding the printer and capturing emissions from all sides.

Air purifiers, which can be used in conjunction with other methods, utilize filters like activated carbon and HEPA to eliminate volatile organic compounds (VOCs) and particulates from the air.

A well-designed ventilation system is essential for reducing health risks associated with inhaling harmful emissions from 3D printing. By combining different filtration methods, you can create a safer printing environment and minimize the impact of printer fumes on your health.

Improving Air Quality With Filters

You can greatly improve the air quality in your 3D printing workspace by incorporating filters that target both particulate and gaseous emissions.

A well-designed Printer Ventilation System should include filters that capture both types of pollutants. Activated carbon filters are effective in removing volatile organic compounds (VOCs) from the air, while High-Efficiency Particulate Air (HEPA) filters can capture 99.97% of particles as small as 0.3 microns, greatly boosting air quality.

Combining HEPA and activated carbon filters provides thorough filtration for both particulates and gases emitted during printing. For even better results, consider using MERV 13-16 filters, which offer superior filtration efficiency for trapping fine particles and improving indoor air quality.

Remember to regularly replace filters to maintain excellent filtration performance and ensure clean air in the workspace. By incorporating these filters into your system, you'll be able to significantly upgrade air quality, creating a healthier and safer environment for you and your 3D printer.

Designing a Safe Printing Environment

By designing a safe printing environment, you can greatly reduce your exposure to harmful emissions and create a healthier workspace. When working with 3D printers, it's crucial to take into account the ventilation and air quality in your printing area. Harmful particles and VOCs emitted during the printing process can negatively impact indoor air quality and your health.

To create a safer environment, take the following into account:

- Utilize fume hoods or enclosures to contain and extract fumes and particles.

- Place your 3D printer near an open window or use ventilation systems like exhaust fans to improve airflow.

- Implement air purifiers to reduce the concentration of harmful particles and odors.

- Regularly maintain your ventilation systems, including cleaning filters and ensuring proper airflow, to guarantee effective fume extraction.

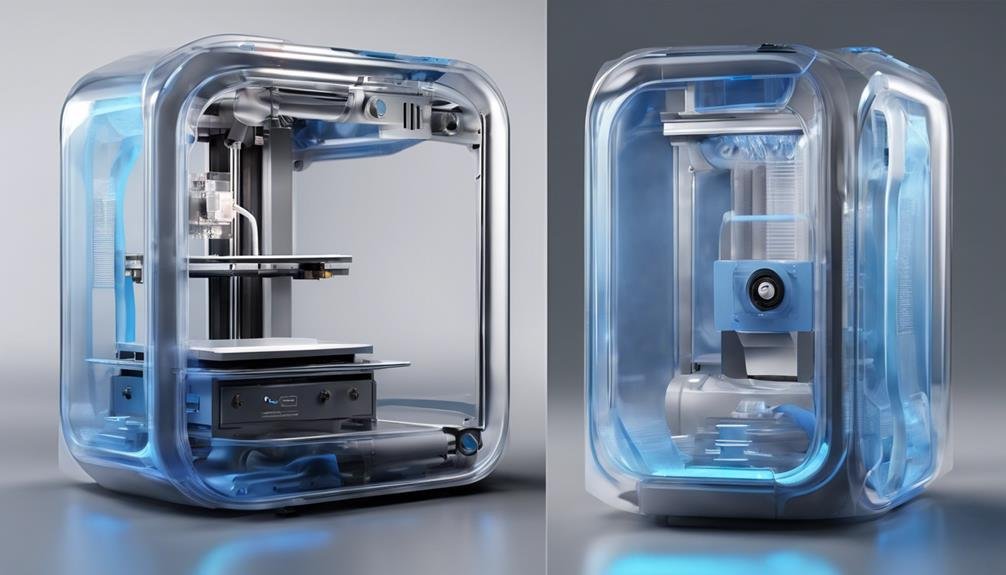

Optimizing Ventilation for Resin Printers

Ventilation is crucial when working with resin printers, as insufficient airflow can lead to serious health issues. Moreover, it's important to consider investing in external ventilation solutions to further enhance the safety of your printing environment.

One effective approach is to use an enclosure with a ventilation system that includes an air filter, such as activated carbon, to minimize VOC emissions. Also, think about incorporating fume extractors or grow tents with flexible ducts to assist in directing harmful particles outside through window exhaust.

Frequently Asked Questions

Do I Need to Ventilate My 3D Printer?

You're right to wonder if you need to ventilate your 3D printer; poor printer safety can compromise indoor air quality, releasing toxic particles that harm respiratory health, making workshop ventilation essential to minimize printing risks.

Do 3D Printer Enclosures Help With Fumes?

You'll breathe easier knowing a well-designed enclosure can greatly decrease fumes, improving air quality and printer safety, especially for indoor printing, while minimizing allergy concerns through effective air filtration, ensuring a healthier printing experience.

How to Make a Ventilation System for a 3D Printer?

When creating a ventilation system, you'll need to take into account fan placement, conduct airflow analysis, and explore ducting options, then select filter types, implement noise reduction measures, and set up system automation and exhaust routing for a safe and efficient setup.

What Filaments Need Ventilation?

You need to ventilate when printing with ABS, Nylon, and ASA, which release hazardous fumes, while PETG and PLA generally don't require it; however, Carbon fiber-infused filaments, PVA, and resin-based filaments also emit harmful airborne particles and odors.

Conclusion

By now, you've gained a thorough understanding of the importance of a well-designed 3D printer exhaust system. You've learned how to choose the right vent system, implement effective fume extraction methods, and improve air quality with filters. It’s crucial to remember that without a proper exhaust system, 3D printing can result in the release of harmful fumes and particles into the air. These pollutants can pose potential health risks to individuals working in the vicinity of the printer. By following the guidelines outlined earlier, you can ensure a safe and healthy environment for yourself and others in your workspace.

You've also explored how to design a safe printing environment and optimize ventilation for resin printers. With this knowledge, you're equipped to create a safe and healthy printing space, ensuring a successful and enjoyable 3D printing experience.

Contents