You can breathe new life into old PLA prints by reusing them. Start by collecting and preparing your old prints, removing supports and debris, and cleaning them to eliminate dust and contaminants. Next, shred the PLA into manageable particles using a shredder or grinder, and set up a filament extruder compatible with PLA material. Then, extrude new PLA filament, adjusting the temperature and diameter controls for consistent thickness. Lastly, spool the recycled PLA filament neatly onto a reel, ready for use in your next 3D printing project. Continue exploring the process to uncover more tips and best practices for reusing PLA filament efficiently.

Collecting and Preparing Old Prints

Collect old PLA prints from failed or unwanted 3D printing projects, and set them aside for recycling. You're taking the initial step towards reusing PLA filament, reducing waste, and conserving resources.

As you gather these old prints, remove any supports or debris that might be attached to them. This guarantees that only pure PLA material is recycled, resulting in high-quality filament.

Next, sort the old PLA prints by color and quality to make certain of consistent filament. This is vital, as different colors and qualities of PLA can impact the final product's properties.

Clean the old PLA prints to eliminate any dust or contaminants that might've accumulated during printing or storage.

Lastly, make sure the old PLA prints are dry and free of moisture, as excess moisture can compromise the recycling process.

Shredding and Breaking Down PLA

How do you efficiently break down your collected PLA prints into recyclable fragments, ready for the next stage of the recycling process?

This pivotal step involves shredding the PLA waste into manageable particles, guaranteeing a smooth extrusion process for creating new filament. You'll need a shredder or grinder to reduce the PLA waste into smaller fragments, which will facilitate the recycling process.

Proper shredding is vital, as it ensures efficient reuse of PLA filament in 3D printing.

When shredding PLA, you're breaking down the material into smaller pieces, making it easier to process and reuse. This step is crucial in the recycling process, as it allows for the creation of new PLA filament.

Setting Up the Filament Extruder

Your filament extruder is now ready to transform the shredded PLA fragments into usable filament, but in the beginning, you need to set it up correctly. Make sure your filament extruder is compatible with PLA material for successful recycling. Set up the extruder in a well-ventilated area with stable positioning for consistent filament production. Follow temperature guidelines (140C-170C) specific to PLA for proper flow rate control during extrusion.

| Parameter | Recommended Setting | Notes |

|---|---|---|

| Temperature | 150C | Ideal temperature for PLA extrusion |

| Extruder Speed | 50 RPM | Adjust for consistent filament diameter |

| Cooling System | Enabled | Prevents overheating and warping |

Calibrate the extruder controls to achieve the desired filament diameter for quality printing results. Lastly, spool the recycled PLA filament neatly onto a spool for convenient use in 3D printing projects. By following these steps, you'll be able to produce high-quality recycled material for your next project.

Extruding New PLA Filament

With the filament extruder set up and calibrated, you're ready to feed in the shredded PLA waste material and start extruding new PLA filament. This process allows you to recycle and create new printer filament from recycled PLA waste, reducing waste and saving you money.

To guarantee ideal flow rate, adjust the extrusion temperature between 140C-170C. As you begin extruding filament, fine-tune the diameter control on the extruder to guarantee consistent filament thickness. This is essential, as inconsistent thickness can affect the quality of your 3D prints.

As the extruder produces the new filament, you'll be amazed at how efficiently you're reusing and recycling PLA waste. By making new filament from recycled PLA, you're not only reducing waste but also reducing your environmental footprint.

With the extruder producing high-quality filament, you'll be ready to create stunning 3D prints that showcase your creativity and innovation.

Spooling and Winding the Filament

Now that you've successfully extruded new PLA filament, it's vital to properly spool and wind it onto a reel to guarantee trouble-free 3D printing and peak performance.

Unlike ABS, PLA filament is more prone to tangling and knotting, making it important to wind it neatly onto a spool. You can do this manually or use a drill to speed up the process.

To achieve a neat and organized spool, use a spooling device or jig to maintain consistent tension and alignment while winding the PLA filament. This will ensure smooth 3D printing and excellent performance.

Properly wound filament on a spool enables convenient handling and storage for future printing projects.

When spooling, keep in mind that neatness is key to preventing tangles and ensuring smooth feeding during 3D printing.

Tips for Reducing PLA Waste

By implementing smart design strategies and optimizing your 3D printing process, you can greatly decrease PLA waste and make a positive impact on the environment.

To reduce plastic waste, integrate supports into your 3D model design or orient parts strategically, which will minimize PLA waste during printing.

Moreover, guarantee proper bed adhesion to avoid failed prints, which can lead to material wastage.

When selecting filaments, choose those made from recycled materials to promote sustainability and reduce the need for new PLA filament.

By supporting recycling programs, you're contributing to the production and use of recycled PLA filament, decreasing the demand for raw material.

Additionally, optimize your support structures in 3D printing to minimize plastic waste and make efficient use of PLA filament.

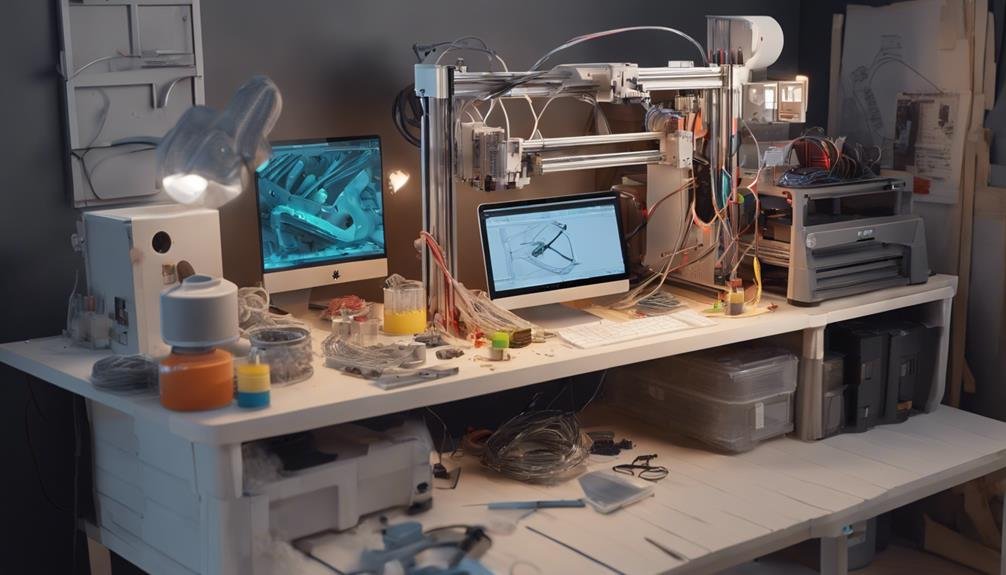

Investing in a Filament Extruder

You can breathe new life into old PLA prints by investing in a filament extruder, a device capable of transforming discarded prints into reusable filament for 3D printing. This cutting-edge machine allows you to reduce waste and save costs on filament purchases.

By recycling PLA material, you'll not only conserve resources but also contribute to environmental conservation efforts. A filament extruder works by melting down old prints to a specific melting temperature, then extruding the molten PLA material through a die to create new filament. This process guarantees that the resulting filament is of high quality, suitable for use in your 3D printer.

With a filament extruder, you can create a sustainable cycle of recycling and reusing PLA material, minimizing waste and reducing your environmental footprint. By investing in a quality filament extruder, you'll be taking a significant step towards a more eco-friendly approach to 3D printing.

Frequently Asked Questions

Is There a Way to Reuse Pla?

You're wondering if you can reuse PLA filament, and the answer is yes! You can recycle it, but be aware of PLA's limitations, such as its temperature sensitivity, and know that reusing it offers environmental benefits through reduced waste and sustainable material properties.

Can You Turn Used Filament Into New Filament?

You can turn used filament into new filament through filament recycling, where melted plastic is reshaped, preserving its material properties, and minimizing thermal degradation, allowing you to reuse high-quality recycled filament for future projects.

How Do You Revive PLA Filaments?

You can revive PLA filaments by controlling temperature to remove moisture, preventing material degradation, and absorption issues; simply dry them in a dehydrator at 45-50°C for a few hours to restore their original properties.

How Many Times Can PLA Be Melted?

You'll find that PLA can withstand multiple melt cycles before thermal degradation sets in, as molecular bonds break down, causing material fatigue, which typically occurs after 3-5 melt cycles, depending on factors like temperature and handling.

Conclusion

By following these steps, you've successfully reused PLA filament, reducing waste and saving resources. Additionally, reusing PLA filament also helps to lower the environmental impact of 3D printing. Furthermore, utilizing multimaterial 3D printing can allow for even more efficient use of resources by incorporating recycled materials into the printing process. By taking these steps, you can not only reduce waste, but also contribute to a more sustainable approach to 3D printing.

You've collected and prepared old prints, shredded and broken down the PLA, set up the filament extruder, extruded new PLA filament, and spooled and wound the final product.

Remember to maintain your extruder, store your filament properly, and continually monitor your process to guarantee high-quality output.

With practice and patience, you'll refine your skills and minimize waste, making you a more sustainable and efficient 3D printing enthusiast.