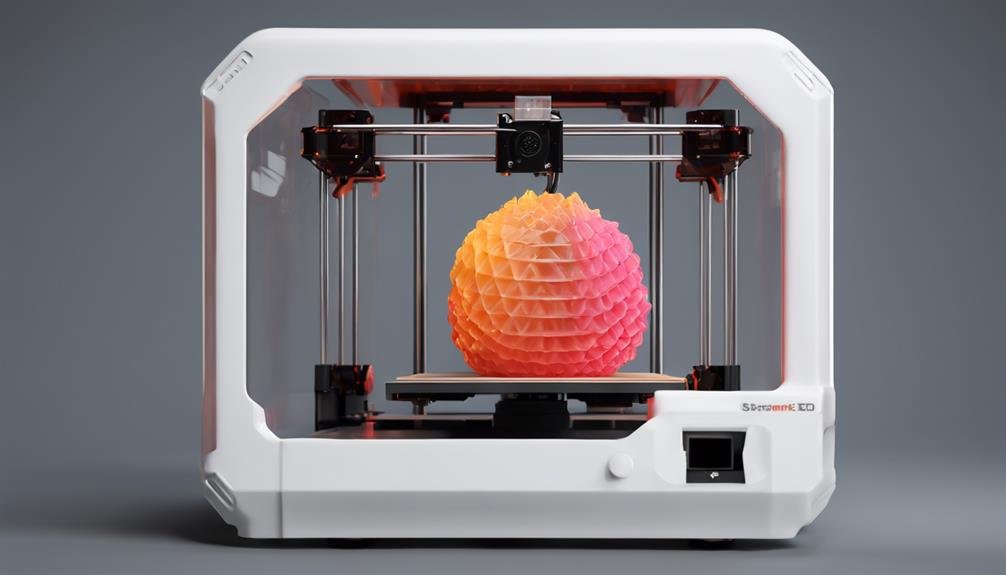

When opting for resin 3D printers, you gain intricate, high-resolution prints for detailed projects like jewelry. The variety of materials includes flexible and transparent resins, perfect for diverse needs. Enjoy smooth surface finishes and water-resistant properties, ideal for lasting, durable items. Though, upkeep is meticulous due to toxic risks and necessary post-processing. Keep in mind the limited build volume as compared to other printer types and the higher resin costs. Choosing resin has its advantages, but handling it carefully and understanding its intricacies are essential. These printers offer a world of possibilities for your detailed creations.

Advantages of Resin 3D Printers

Resin 3D printers consistently deliver high-resolution prints with intricate detail, making them a popular choice for a wide range of applications. Their ability to produce highly detailed and complex designs is unmatched, especially for small-scale production items like jewelry.

These printers offer a diverse selection of materials, including flexible, rigid, and transparent resins, catering to different project requirements. The prints from resin 3D printers possess a smooth surface finish, ensuring quality outcomes. Moreover, they exhibit water-resistant properties, adding durability to the final products.

One notable advantage is the minimal impact of supports on the surface quality of the prints, allowing for cleaner and more refined results. Transparent resins, in particular, showcase the printer's capability to produce objects with exceptional clarity.

In general, resin 3D printers are a reliable choice for achieving intricate designs with precision and consistency while maintaining a professional finish.

High Resolution Output

Achieving high resolution output is a key strength of resin 3D printers, allowing for the detailed reproduction of intricate designs and fine textures with precision. These printers excel in capturing fine details, resulting in smooth surfaces with minimal visible layer lines.

The technology behind resin printing enables the creation of sharp features and complex geometries, enhancing the general quality of the printed objects. Whether you're looking to produce detailed prototypes or intricate jewelry, the superior resolution of resin printers ensures that even the smallest intricacies are faithfully replicated.

Compared to filament printers, resin 3D printers stand out for their ability to render fine textures and intricate patterns with remarkable accuracy. This capability makes resin printers a preferred choice for tasks that require a high level of detail and precision, offering a level of output quality that's unmatched in the world of 3D printing.

Wide Material Options

With resin 3D printers, you have access to a diverse selection of material options suitable for different applications and customization needs. The wide range of materials available allows for the creation of unique prints tailored to specific applications.

Here are some key points to explore:

- Specific Applications: Resin printers enable the use of different materials like flexible, rigid, transparent, and specialty resins, making them suitable for a variety of applications such as dental aligners, jewelry, prototypes, and functional parts.

- Customization: The availability of diverse materials in resin printing allows for customization and optimization based on the desired characteristics of the final print.

- Specialty Resins: Resin printers can utilize specialty resins like castable resin for jewelry making or biocompatible resins for medical applications, expanding the range of possibilities for creating tailored prints.

- Unique Prints: The variety of materials in resin printing opens up opportunities for producing unique and customized 3D prints that meet specific needs and requirements.

The broad spectrum of material options in resin printing enriches the versatility and adaptability of this technology for different industries and projects.

Water-Resistant Prints

Expanding on the versatility of resin 3D printing, water-resistant prints offer a durable solution for applications needing exposure to moisture. Resin prints are inherently water-resistant, making them ideal for outdoor use and underwater applications where traditional filament prints would fail. The ability of resin prints to withstand water exposure without compromising their structural integrity and surface quality is a significant advantage. These water-resistant resin prints find extensive applications in marine industries, architectural models, and functional prototypes due to their durability and longevity. Whether used in creating intricate architectural designs or functional prototypes for testing, the water-resistant property of resin prints guarantees the objects maintain their shape and quality over time. This longevity and structural integrity make resin prints a reliable choice for projects requiring resilience against moisture. The table below summarizes the key aspects of water-resistant resin prints:

| Key Aspect | Details |

|---|---|

| Durability | Ideal for outdoor use and underwater applications |

| Longevity | Ensures lasting quality and structural integrity |

| Application Areas | Widely used in marine industries, architectural models, and functional prototypes |

Minimal Impact of Supports

Resin 3D printers exhibit minimal impact from support structures on the surface quality of prints, resulting in smoother and cleaner finishes. This advantage stems from the reduced need for support structures in resin printing, making post-processing easier and less time-consuming.

When supports are necessary, they're typically easier to remove and leave minimal marks or blemishes on the final print. The prints maintain intricate details and delicate features without compromise. Consequently, the minimal impact of supports on resin prints allows for the creation of highly detailed and complex objects with superior surface quality.

- Supports in resin printing are easier to remove compared to filament printing.

- Minimal marks or blemishes are left on the final print due to the support removal process.

- Resin prints maintain intricate details and delicate features after support removal.

- The minimal impact of supports allows for the creation of highly detailed and complex objects with superior surface quality.

Disadvantages of Resin 3D Printers

Compared to filament printers, resin 3D printers typically come with a higher initial cost. This cost can be a barrier for those looking to venture into 3D printing. The liquid resin used in resin printers can emit toxic fumes during the printing process, requiring proper ventilation to guarantee safety. Post-processing for resin prints can be more cumbersome than with filament printers, involving steps such as cleaning and curing, which adds time and effort to the printing process. Furthermore, resin has a limited shelf-life, meaning that unused resin can degrade over time, impacting the quality of prints. Another drawback is the limited printing size of resin 3D printers, restricting the size of objects that can be produced compared to filament printers. Below is a table summarizing the disadvantages of resin 3D printers:

| Disadvantages of Resin 3D Printers |

|---|

| Higher initial cost |

| Toxic fumes during printing |

| Messy and time-consuming post-processing |

| Limited printing size |

Toxic Fumes and Post-Processing

During the resin 3D printing process, adequate ventilation is vital to mitigate the risk of exposure to toxic fumes. When working with resin printers, be mindful of the following aspects of post-processing:

- Cleaning in Isopropyl Alcohol: After printing, parts need to be cleaned in isopropyl alcohol to remove excess resin. Proper ventilation is critical during this step to avoid inhalation of fumes.

- UV Curing: Resin prints require UV curing to harden the material fully. This step guarantees the parts are durable and ready for use.

- Support Structures: Support structures used during printing may leave marks that require sanding during post-processing, affecting the final appearance.

- Hazardous Disposal: Proper handling and disposal of used resin and cleaning solutions are necessary due to their potentially hazardous nature. Always follow local regulations for disposal.

Frequently Asked Questions

What Are the Downsides of a Resin 3D Printer?

When utilizing a resin 3D printer, there are drawbacks to take into account. Health risks, material costs, post-processing, limited build volume, resin disposal, curing time, print speed, maintenance requirements, resin spills, and skin irritation are factors to be mindful of.

Which Is Better, a 3D Printer or a Resin Printer?

When deciding between a 3D printer and a resin printer, weigh factors like cost, speed, quality, materials, post-processing, maintenance, size limits, environmental impact, learning curve, and safety. Consider your project needs carefully for the best choice.

How Bad Are Resin 3D Printer Fumes?

Breathing in resin 3D printer fumes can pose health risks like respiratory irritation and headaches. Proper ventilation and using low odor resins can help. Wearing protective gear and considering long-term effects are essential for your safety and well-being.

How Messy Are Resin 3D Printers?

Resin 3D printers can get messy. Spills happen, requiring careful cleanup. Safety is key with protective gear, proper ventilation, and odor concerns. Post-printing mess and resin disposal need attention. Keep a tidy workspace to minimize hazards.

Conclusion

To sum up, resin 3D printers offer high resolution output, a wide range of material options, and water-resistant prints. However, they come with the downside of toxic fumes during printing and require post-processing for best results.

Understanding the pros and cons of resin 3D printers is crucial for making informed decisions when choosing a 3D printing technology. Resin 3D printers offer high resolution and smooth surface finishes, making them ideal for creating highly detailed objects. However, the resin printing technology also comes with its drawbacks, such as the need for post-processing to remove excess resin and the potential health hazards from handling the uncured resin. It’s essential to weigh these factors carefully when considering resin 3D printing for your projects.