Car 3D printing offers numerous benefits like cost savings and customization options, ushering in a new age of efficiency in manufacturing and design. Techniques improve parts with intricate designs, reduced waste, and enhanced strength. Ensuring durability involves carbon fiber reinforcement techniques and meticulous quality control. Detailed finishing touches include fine line tapes, paint detailing, and seamless appearances. Combining 3D printing with traditional methods, like carbon fiber integration, leads to stabilized, high-quality car parts. Embrace automotive innovation through 3D printing for cutting-edge designs and manufacturing processes, revealing craftsmanship and precision in the final product.

Benefits of Car 3D Printing

Car 3D printing offers a range of advantages that revolutionize the way car parts are manufactured and designed. One significant benefit is cost savings. By utilizing 3D printing technology, car manufacturers can reduce production costs associated with traditional manufacturing methods.

Customization options are another key advantage of car 3D printing. Individuals can now tailor car parts to their specific preferences and needs, providing a level of personalization that was previously unattainable. This level of customization allows for unique designs and functionalities that cater to individual tastes.

With cost savings and customization options at the forefront, car 3D printing embodies a shift towards efficient and tailored manufacturing processes in the automotive industry. By embracing this cutting-edge technology, manufacturers can streamline production, reduce expenses, and offer consumers a personalized driving experience.

The ability to create custom car parts at a lower cost signifies a new phase in automotive design and manufacturing.

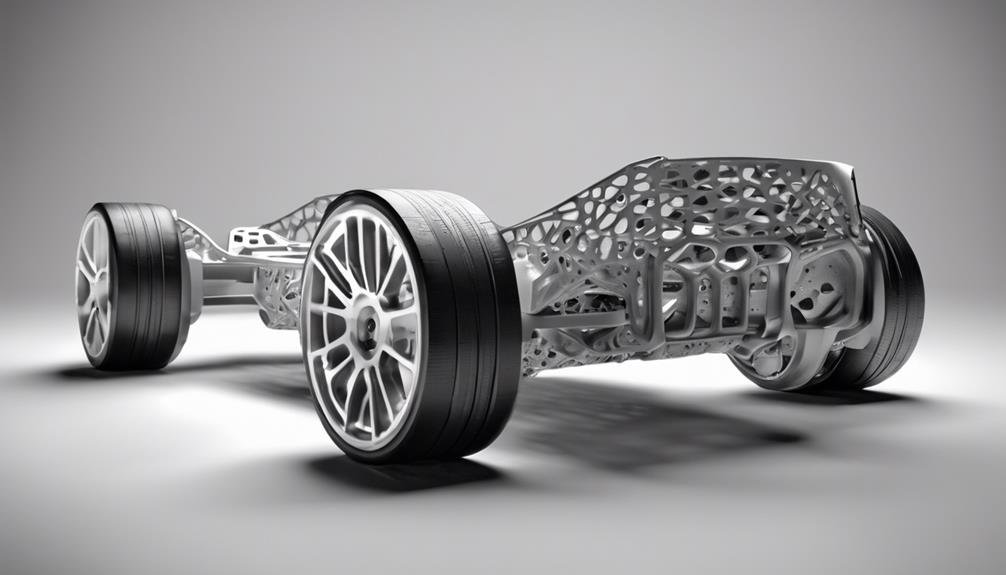

Advanced Techniques for Car Parts

Utilizing cutting-edge methods and materials, the production of car parts has evolved to incorporate advanced techniques for improved strength and precision. When considering 3D printing for car parts, customization options play a significant role. This technology allows for intricate designs that can be tailored to specific needs, offering a level of flexibility that traditional manufacturing methods struggle to match. Additionally, 3D printing provides cost efficiency by reducing material waste and enabling the creation of complex geometries in a single process.

| Advanced Techniques for Car Parts | Benefits |

|---|---|

| Customization Options | Allows intricate and tailored designs |

| Cost Efficiency | Reduces material waste and enables complex geometries |

Incorporating these advanced techniques not only improves the structural integrity of car parts but also opens up a range of possibilities for designers and manufacturers seeking to optimize strength, precision, and performance.

Ensuring Durability and Strength

To guarantee the durability and strength of 3D printed car parts, incorporating carbon fiber reinforcement is a common practice. By selecting the right materials and utilizing advanced techniques, you can ensure the quality and longevity of your printed components.

- Weaving carbon fiber in specific patterns like V weave Herringbone style improves structural integrity.

- Stabilized carbon fiber with a 3K weave provides stability and strength to the final car parts.

- The direction of the carbon fiber weave must be carefully chosen to optimize the strength of the printed components.

Quality control measures should be implemented throughout the printing process to confirm the desired durability and strength. Proper material selection, particularly in relation to carbon fiber reinforcement, plays a vital role in improving the performance of 3D printed car models.

Attention to Detail in Finishing

With precise detailing, achieving a polished appearance on 3D printed car fenders involves using fine line tape for accuracy and guiding the sanding process. Paint detailing and surface refinement play significant roles in improving the final look of the fenders.

Adding body line detail where sections meet ensures a seamless appearance, while sanding and shaping are necessary for a smooth finish. To further differentiate and enhance visual appeal, black lines can be incorporated into the design.

Attention to detail in finishing extends to using tape to mark and guide the sanding process, guaranteeing precise detailing work. By carefully considering these aspects, the overall aesthetic of 3D printed car fenders can be enhanced to a professional level.

Paying close attention to paint detailing and surface refinement guarantees a high-quality finish that meets the standards of traditional manufacturing methods.

Combining 3D Printing and Traditional Methods

Combining 3D printing with traditional methods involves integrating additive manufacturing with conventional techniques like bonding, reinforcing, and finishing to improve the general quality and strength of the final product. Hybrid manufacturing techniques play an important role in enhancing structural integration, allowing for the creation of robust components.

Here are important aspects to think about:

- Materials Integration: Incorporating materials like carbon fiber into the 3D printing process boosts the strength and durability of the final product.

- Finishing Touches: Traditional methods such as sanding and detailing are crucial for achieving a smooth and flawless surface finish on 3D printed car parts.

- Reinforcement Techniques: Using epoxy bonding and screws in combination with 3D printed parts ensures the overall stability and longevity of the components.

- Precision Planning: The process of combining 3D printing and traditional methods demands meticulous planning, attention to detail, and expertise for successful outcomes.

- Quality Control: Regular quality checks and testing are necessary to guarantee the integrity and reliability of the final product in hybrid manufacturing processes.

Innovation in Automotive Manufacturing

In automotive manufacturing, progress drives advancements in technology and design, revolutionizing the industry. Sustainability practices are becoming increasingly prevalent, with 3D printing offering a more eco-friendly approach to producing car parts. This method reduces waste and energy consumption compared to traditional manufacturing processes.

Design creativity flourishes as 3D printing allows for intricate and customizable car models, catering to both practical and aesthetic needs. With 3D printing, car enthusiasts can now create personalized designs that reflect their individual tastes and preferences. This technology also provides the flexibility to produce unique and tailor-made parts that may not be readily available on the market. Moreover, the advent of iphone 3d scanning has further revolutionized the possibilities, allowing for precise measurements and detailed reproductions of existing car components. This combination of design innovation and advanced scanning techniques has opened up a world of opportunities for crafting truly one-of-a-kind vehicles.

Car manufacturers are harnessing 3D printing technology to create complex parts with precision and efficiency. By integrating sustainability practices into their production processes, companies aren't only reducing their environmental impact but also optimizing resource management.

Designers are leveraging 3D printing to offer fully customized car projects, pushing the boundaries of traditional manufacturing methods.

The collaboration between skilled designers and freelancers in the automotive sector enables the realization of unique and tailored creations. This forward-thinking approach fosters a diverse range of expertise, providing enthusiasts with multiple options for custom automotive projects.

The integration of 3D printing in automotive manufacturing represents a significant leap towards sustainable practices and design creativity in the industry.

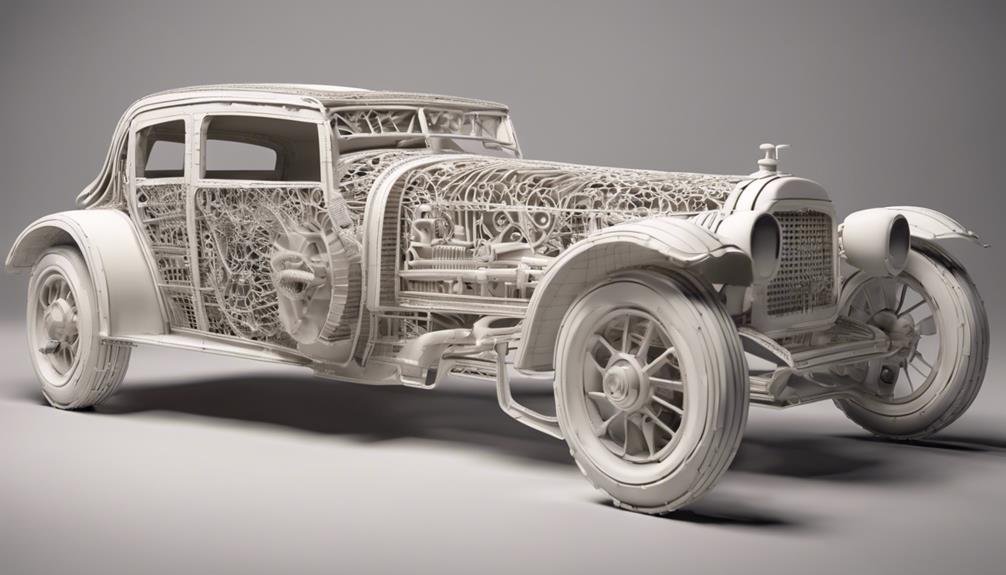

Showcasing Craftsmanship

Car manufacturers demonstrate their expertise and dedication to precision by showcasing intricate craftsmanship in the 3D printing of car components. This Craftsmanship showcase involves different meticulous steps to guarantee a high-quality final product that exemplifies skilled craftsmanship in 3D printing:

- Fenders were printed in 7 separate sections totaling over 200 hours of printing time.

- Carbon fiber reinforcement was strategically woven in V weave Herringbone style for improved design and structural integrity.

- Meticulous sanding, shaping, and bonding using dp420 epoxy and sheet metal screws ensured a seamless and durable finish.

- Fine line tape guided sanding to create precise body lines, highlighting attention to detail.

- Stabilized carbon fiber and a satin clear finish were used to contribute to the overall quality of the final product, showcasing the manufacturer's dedication to Design innovation.

Frequently Asked Questions

How Much Would It Cost to 3D Print a Car?

For a cost estimation on 3D printing, consider factors like size, complexity, and materials. Material options range from $20 to $500 or more depending on the model. Quality of the printer impacts cost.

Can 3D Printing Be Used for Cars?

Yes, 3D printing can be utilized for cars. It offers sustainability benefits like reduced material waste and economic feasibility through cost-effective prototyping. Manufacturers and designers harness 3D printing for efficient production and intricate car part creation.

Is There Anything Illegal to 3D Print?

When it pertains to 3D printing, it's essential to be aware of the legalities. Copyright infringement through 3D printing and producing firearms illegally are serious offenses. Research and understand the rules to avoid legal trouble.

Can I 3D Print My Own Car Parts?

You can 3D print your own car parts for custom car mods and DIY car repairs. 3D printing offers flexibility in design and production, enabling you to create unique and functional components tailored to your needs.

Conclusion

To sum up, car 3D printing offers a multitude of benefits, from advanced techniques for producing car parts to ensuring durability and strength.

Attention to detail in finishing and the combination of 3D printing with traditional methods showcase innovation in automotive manufacturing, highlighting the craftsmanship involved.

This cutting-edge technology is revolutionizing the way cars are made, leading to more efficient and customizable production processes.