When selecting label materials, you're making a critical decision that impacts your brand's appearance, communication, and regulatory compliance. Industry-specific solutions require consideration of label properties and adhesives, such as acrylic-based adhesives for versatility and durability, and rubber-based adhesives for cost-effectiveness and good initial tack. Applications and use cases likewise play a role, such as chemical-resistant labels for the chemical industry, food-grade materials for food and beverage, and UL certification marks for electrical labels. By understanding your industry's unique needs, you can choose the right label material, adhesive, and finish to guarantee optimal performance – and find the perfect fit for your product.

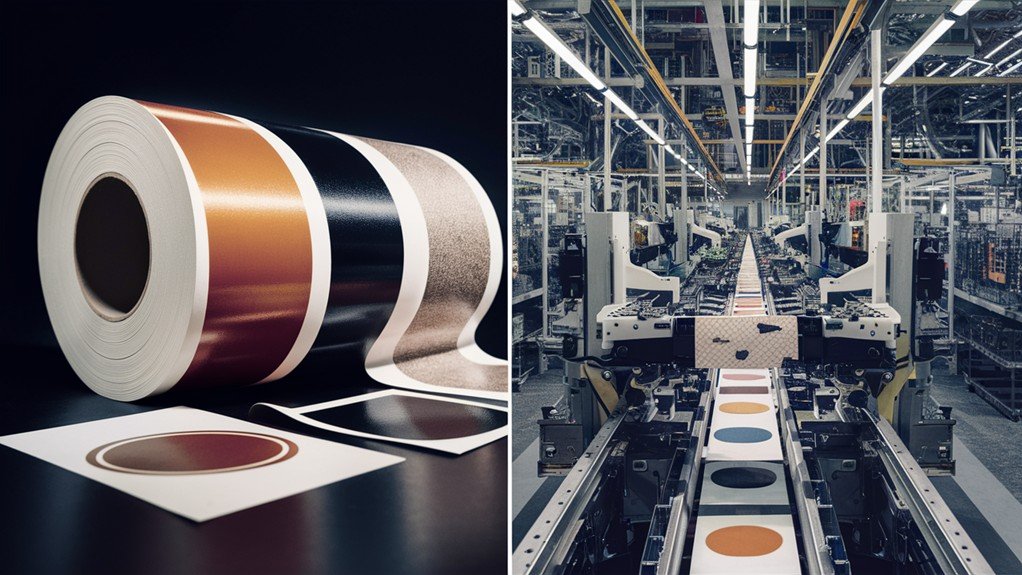

Label Materials and Types

You must also take into account the type of label that suits your needs.

Pressure-sensitive labels are widely used because of their ease of application, while self-laminating labels provide additional protection against environmental factors.

For extreme conditions, such as high temperatures and chemical exposure, specialty materials like polyimide and polyvinyl fluoride are ideal for aerospace and chemical processing applications.

Thermal label types, including direct thermal and thermal transfer, vary as far as durability is concerned.

Thermal transfer labels offer longer-lasting prints suitable for shipping and pharmaceuticals.

Label Properties and Adhesives

When choosing label materials, the right adhesive is just as important as the type of label itself. Adhesive quality is vital for label adhesion and longevity, offering different options to cater to specific needs.

You'll want to take into account the type of adhesive that suits your application, such as acrylic-based adhesives known for their versatility and durability, or rubber-based adhesives offering lower cost and good initial tack.

Adhesives can likewise be categorized based on their removability, with options for permanent, removable, and repositionable adhesives. Permanent adhesives provide strong bonds suitable for long-term applications, while removable adhesives allow for easy removal without residue.

Repositionable adhesives offer flexibility in indoor environments, allowing labels to be moved or adjusted without compromising adhesion strength.

Some key properties to keep in mind when selecting an adhesive include:

- Chemical resistance, particularly in industrial applications where exposure to harsh substances is common

- Temperature-related properties, such as heat-resistant adhesives designed to withstand increased temperatures

- Cryogenic adhesives suited for low-temperature applications

Applications and Use Cases

Industry-specific label applications come with their own set of unique challenges. You need to take into account different factors such as durability, visibility, and compliance when selecting label materials. Distinct industries require specific label properties to effectively communicate information and guarantee safety.

Here are some examples of industry-specific label applications and their requirements:

| Industry | Label Requirements | Material Suggestions |

|---|---|---|

| Chemical | Harsh environment, clear hazard communication | Durable materials with CLP compliance |

| Food and Drink | High-quality, attention-grabbing, nutritional information | Specialized papers or films with food-grade inks |

| Cosmetic | Visual appeal, regulatory compliance, moisture resistance | Specialized materials with waterproof coatings |

| E-liquid and Vape | High durability, legible information, strict regulations | Durable materials with waterproof coatings and UV resistance |

| Electrical | Resistance to electrical currents, safety, and compliance | Polyolefin or vinyl materials with electrical insulation |

When selecting label materials, you must take into account these industry-specific requirements to guarantee effective communication, safety, and compliance. By choosing the right materials, you can create labels that meet the unique challenges of your industry and effectively convey critical information.

Compliance and Regulations

Adherence to regulatory standards is a critical component of label material selection. When choosing a label material, you must consider the specific regulations that govern your industry. Non-compliance or mislabeling can result in significant financial repercussions, including fines, product recalls, and damage to brand reputation.

Different industries have distinct labeling requirements. For instance, the FDA oversees food and beverage labels, requiring clear display of nutritional facts and ingredient lists. Likewise, the CLP guidelines for chemical labels and RoHS compliance for electronic products in the EU have strict regulations. UL certification marks as well signify compliance with safety standards.

To guarantee compliance, consider the following:

- FDA regulations for food and beverage labels, requiring clear display of nutritional facts and ingredient lists

- CLP guidelines for chemical labels, enforcing strict regulations on labeling practices

- RoHS compliance for electronic products in the EU, limiting the use of specific hazardous materials in labels and packaging

Label Optimization and Finishes

Beyond regulatory adherence, the appearance of your label plays an important role in capturing consumer attention and driving sales. In terms of label optimization and finishes, you have several options to choose from, each with its unique benefits.

Finishes can greatly improve the visual appeal of your label. Gloss finishes, for instance, make colors more vibrant and labels more noticeable on store shelves. In contrast, matte finishes offer a non-reflective surface, improving readability and contrast, making them ideal for products with extensive text. Satin finishes provide a subtle sheen, balancing visual appeal with practicality, while reflective finishes increase visibility in low-light conditions.

The type of topcoat you choose is likewise vital, as it directly impacts total label durability and performance. When selecting a finish, consider the environment in which your product will be sold and used.

For example, if your product will be exposed to extreme temperatures or moisture, a more durable topcoat may be necessary. By carefully choosing the right finish and topcoat, you can create labels that not only capture consumer attention but endure the elements.

Choosing the Right Label Material

Your product's packaging is the initial thing consumers see, and the label material can make or break its general appearance. When choosing the right label material, you need to take into account the specific environmental conditions that your product will be exposed to. This includes factors such as moisture, UV light, and temperature extremes, which can affect label durability and performance.

The label material you select is also contingent on the industry you're in. For example, if you're in the food and beverage industry, polypropylene labels are a popular choice because of their non-toxic properties and resistance to water, oil, and solvents. Likewise, chemical labels must comply with CLP guidelines and pharmaceutical labels require materials with chemical resistance and tamper-evident features.

Some key factors to take into account when choosing a label material include:

- The surface material of your product and how it will affect label adhesion and appearance

- The level of environmental resistance required for your label

- Any industry-specific regulations or guidelines that apply to your product

Specialty Label Materials

Other specialty label materials include polyvinyl fluoride, which excels in outdoor signage owing to its chemical and weather resistance.

Polyurethane labels are ideal for industrial labeling needs, maintaining their quality and adhesion even in harsh conditions.

Nylon labels are specifically engineered to conform to irregular surfaces, making them perfect for control panels and cables.

Some industries require labels that can withstand harsh chemicals and UV radiation.

Polyvinylidene fluoride labels are a popular choice for chemical processing environments because of their resistance to these elements.

When selecting a specialty label material, consider the unique demands of your application and choose a material that's specifically designed to meet those needs.

Adhesive Options and Considerations

When choosing a label material, you've considered factors like chemical resistance and surface conformation.

Now, it's time to think about the adhesive that will fasten your label in place. The right adhesive can make all the difference in the performance and longevity of your label.

Adhesive options for labels include permanent, removable, and repositionable adhesives. Rubber-based adhesives are cost-effective, but may not be suitable for high-temperature environments, whereas acrylic-based adhesives offer superior durability and versatility.

Consider the following key factors when selecting an adhesive:

- Adhesive type: Permanent adhesives for long-lasting applications, removable adhesives for temporary use without residue, and repositionable adhesives for adjustments during application.

- Surface compatibility: Flexible adhesives for curved or uneven surfaces, guaranteeing reliable adhesion.

- Regulatory compliance: Essential for products in the food, pharmaceutical, and chemical industries to avoid safety hazards and maintain product integrity.

Industry-Specific Labeling Solutions

Industry-specific labeling solutions cater to different sectors, each with its unique set of requirements, challenges, and regulations.

Chemical and Hazardous Materials Labels

When labeling chemicals and hazardous materials, you must comply with the CLP guidelines, which require careful selection of materials and clear hazard communication to guarantee safety in handling hazardous substances.

Consumer Product Labels

For industries like food and drink, cosmetics, and e-liquids, labels play a vital role in capturing consumer attention and conveying important information.

For example, food and drink labels must integrate regulatory compliance with nutritional information, while cosmetic labels require durability and adherence to current regulations.

E-liquid labels face the challenge of presenting legible information in small spaces while guaranteeing compliance with industry regulations.

Specialty Labels

Specialty labels, tailored for niche markets such as pet foods and hand sanitizers, often use unique materials and finishes to improve brand perception and meet specific regulatory standards.

Label Durability and Performance

Behind every effective label lies a well-chosen material that balances durability and performance. When selecting a label material, you must consider the environmental conditions in which the label will be used, in addition to the level of performance required.

Different materials offer varying levels of durability and resistance to elements such as moisture, chemicals, and extreme temperatures.

For instance, consider the following scenarios:

- Harsh environments: Polyester labels are ideal for outdoor use or in areas exposed to chemicals, since they offer high resistance to moisture and chemicals.

- Food and beverage packaging: Polypropylene (PP) labels provide flexibility and excellent resistance to water, oil, and solvents, making them suitable for applications where safety and longevity are critical.

- High-temperature applications: Specialty labels, such as polyimide, are designed to endure extreme temperatures and conditions, making them suitable for aerospace and electronic applications where high durability is vital.

Frequently Asked Questions

Can I Use the Same Label Material for Different Products?

You might think you can use the same label material for different products, but it's not that simple. Different products have unique requirements, and one material might not meet all their needs or regulations.

Are Eco-Friendly Labels More Expensive Than Standard Options?

You're likely wondering if eco-friendly labels will strain your finances. Generally, they can be more expensive than standard options, but you're investing in sustainability and a positive brand image that may offset the extra cost.

How Does Label Material Choice Affect Brand Image?

You choose a label material that reflects your brand values, and it directly impacts how customers perceive your image. High-quality materials convey a premium feel, while eco-friendly options showcase your commitment to sustainability.

Can I Design Custom Labels for Unique Packaging Shapes?

You can design custom labels for unique packaging shapes by using digital printing and cutting tools that accommodate different shapes and sizes, allowing you to create labels that perfectly fit your product's distinct packaging.

Are There Label Materials Suitable for High-Temperature Environments?

You're working in high-temperature environments and need labels that can withstand the heat. Don't worry, there are materials designed for this, such as ceramic, polyimide, or Kapton labels that can handle extreme temperatures without losing adhesion.

Contents

- 1 Label Materials and Types

- 2 Label Properties and Adhesives

- 3 Applications and Use Cases

- 4 Compliance and Regulations

- 5 Label Optimization and Finishes

- 6 Choosing the Right Label Material

- 7 Specialty Label Materials

- 8 Adhesive Options and Considerations

- 9 Industry-Specific Labeling Solutions

- 10 Label Durability and Performance

- 11 Frequently Asked Questions

- 11.1 Can I Use the Same Label Material for Different Products?

- 11.2 Are Eco-Friendly Labels More Expensive Than Standard Options?

- 11.3 How Does Label Material Choice Affect Brand Image?

- 11.4 Can I Design Custom Labels for Unique Packaging Shapes?

- 11.5 Are There Label Materials Suitable for High-Temperature Environments?