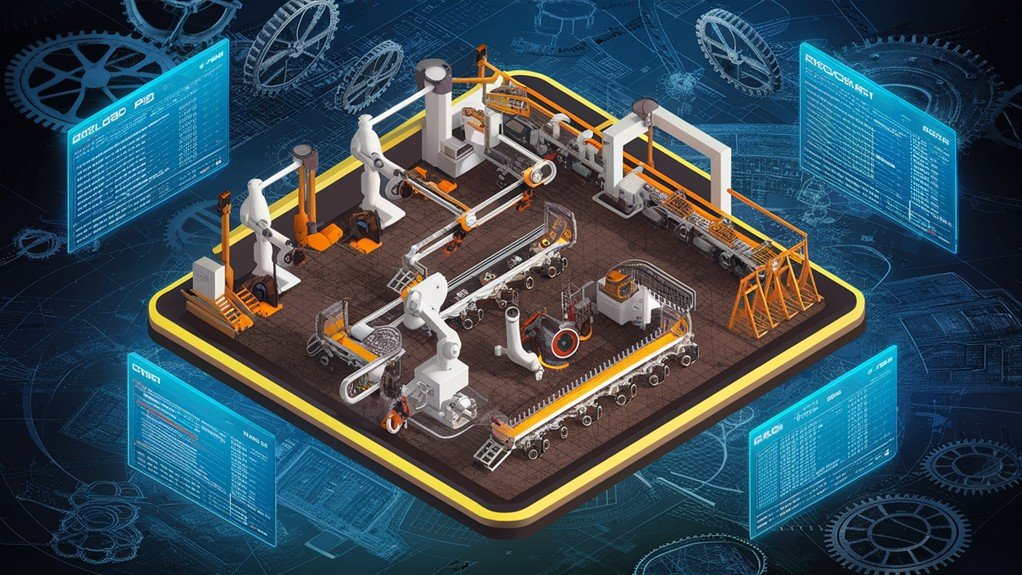

As you navigate the complex landscape of label production planning, you'll face challenges like shorter run lengths, multiple versions, and machine breakdowns that can disrupt even the most well-planned schedules. To overcome these obstacles, you'll need effective scheduling systems that provide real-time feedback, production slot reservation, and milestone tracking. Advanced tools like MIS modules, visual aids, and cloud-based software can likewise improve collaboration and flexibility. By implementing these strategies, you'll boost transparency, efficiency, and coordination, while minimizing lead times and waste. Now, find out how to tailor your approach to meet the unique demands of your operation.

Understanding Production Scheduling Complexity

In today's label printing landscape, you're likely no stranger to the complexities of production scheduling. With shorter run lengths, multiple versions, and special finishing requirements, meeting due dates can be a formidable challenge.

Add to that the unpredictability of machine breakdowns and employee absences, and you'll need to be adaptable to stay on track.

Effective scheduling involves more than just prioritizing jobs by due date. You must consider factors like material and size to optimize production flows.

Batching jobs by these criteria can lead to inefficiencies, so it's crucial to strike a balance between operational efficiency and timely deliveries.

Real-time feedback mechanisms and visibility of machine capacity are vital for enhancing scheduling accuracy.

By integrating advanced scheduling tools with Management Information Systems (MIS), you can better track job statuses, resource efficiency, and identify potential bottlenecks in the production process.

This level of insight allows you to make informed decisions and adjustments to guarantee smooth production flows.

Effective Scheduling Systems and Features

Several effective scheduling systems are available to help you streamline your label production process. These systems provide a clear view of production sequences, allowing you to sort and group jobs based on different timeframes to improve management efficiency.

| Feature | Description |

|---|---|

| Real-time Feedback | Mechanisms that provide instant updates on production progress |

| Production Slot Reservation | Allocate specific time slots for each job to guarantee timely completion |

| Milestone Tracking | Identify and track key stages of the production process |

| Integration with Automation Engines | Streamline pre-press processes for increased efficiency |

Key features of scheduling systems include real-time feedback mechanisms, reservation of production slots, milestone tracking, and integration with automation engines for pre-press processes. Moreover, advanced scheduling tools can analyze machine capacity and identify future bottlenecks, facilitating better decision-making for resource allocation and production flow. Implementing a Management Information System (MIS) module improves visibility throughout the production process, from job approval to shipping, providing press operators with direct access to schedules and increasing overall operational effectiveness.

Advanced Tools for Production Scheduling

You've implemented an effective scheduling system, now it's time to take your label production planning to the next level with advanced tools.

These advanced tools provide improved visibility, flexibility, and accuracy in your production scheduling.

MIS modules offer detailed visibility throughout the production process, from job approval to shipping, enabling efficient management of label production schedules.

Visual aids like Magnetic Planning Boards and Card Planning Boards help teams manage complex label production tasks more effectively, providing broad overviews and extensive job information.

Job tracking terminals provide real-time updates on production statuses, allowing for immediate adjustments to schedules and alerting operators to out-of-sequence jobs that could disrupt workflow.

Cloud-based scheduling software boosts collaboration and flexibility, allowing teams to adapt quickly to changes in production demand while maintaining accuracy in resource allocation and job tracking.

Integration with automation engines for pre-press processes streamlines production scheduling, reducing manual input errors and improving general efficiency in label manufacturing.

Benefits and Flexibility of Scheduling

Frequently, effective production scheduling is the linchpin that holds together a well-oiled label production machine. By implementing a well-planned schedule, you can reap numerous benefits that improve your label production process.

| Benefits | Description |

|---|---|

| Improved Transparency | Boosts visibility of production plans, allowing for better management of progress and capacity across different departments. |

| Increased Efficiency | Minimizes work in process (WIP) inventories and lead times, leading to increased efficiency and reduced operational costs. |

| Flexibility | Allows manufacturers to quickly adapt to changes in production environments, such as unexpected delays or resource availability issues. |

| Improved Coordination | Promotes timely job releases, improving coordination among teams, and increasing total productivity and responsiveness to customer demands. |

With effective scheduling, you can identify resource conflicts and backlogs promptly, supporting seamless production flow and maintaining high standards of quality control. This flexibility in scheduling allows you to respond quickly to changes in production environments, ensuring that your label production machine runs smoothly and efficiently.

Quality Control and Operational Efficiency

As you've optimized your production scheduling, it's time to focus on the next fundamental component of your label production machine: quality control and operational efficiency.

Regular audits guarantee compliance with industry standards and reduce defects. Implementing a strong Management Information System (MIS) provides real-time data on production processes, enabling quick identification of bottlenecks and quality issues.

To maintain consistent quality standards, regular training on quality protocols for staff is critical. This empowers employees to recognize and address potential quality control issues proactively.

Effective inventory control strategies for raw materials and finished goods play a significant role in operational efficiency. They help minimize waste and guarantee that production schedules are met without delays.

Integrating quality metrics into production processes promotes continuous improvement, enabling accurate job costing and enhancing general productivity through better decision-making based on performance data.

Implementing Production Planning and Scheduling

Effective production planning and scheduling is the backbone of a successful label production operation. It's what guarantees you meet deadlines, optimize machine capacities, and allocate resources efficiently across departments.

To get it right, you need real-time visibility into machine capacities and job sequences.

Here are three key strategies to help you implement effective production planning and scheduling:

- Utilize advanced scheduling tools: Management Information Systems (MIS) can considerably improve tracking of production progress and resource allocation. Look for tools with rescheduling capabilities, such as click-and-drag features, to accommodate unexpected changes or delays.

- Implement a thorough bills of materials (BOM) management system: This guarantees accurate tracking of raw materials and minimizes the risk of stockouts during production.

- Conduct regular audits and staff training: Regular audits and staff training on quality control protocols are crucial to maintain compliance with industry standards and improve general operational efficiency in label production.

Frequently Asked Questions

How to Make Production Planning and Scheduling?

You start by forecasting demand to anticipate customer needs, then create a master production schedule to outline activities, map material flow, and utilize software to automate tasks, regularly reviewing and adjusting schedules to maintain efficiency.

What Are the 5 Steps in Production Planning?

You're wondering what the 5 steps in production planning are. Well, you need to forecast demand, assess your capacity, plan and procure materials, schedule production, and allocate resources – these steps guarantee you're producing efficiently and meeting customer needs.

What Is the MRP Production Schedule?

You're working with an MRP production schedule, which determines the quantity and timing of raw materials and components needed for production based on demand forecasts and inventory levels, ensuring you have what you need, when you need it.

What Is the Production Schedule in a Production Plan?

You create a production schedule in a production plan to outline when specific manufacturing tasks will occur, ensuring efficient resource allocation and time management. It includes item specs, processes, materials, labor, and equipment availability to avoid stockouts and reduce costs.

Contents