The purpose of a 3D printer is to revolutionize manufacturing by constructing intricate objects layer by layer. It transforms digital designs into physical reality with precision, allowing for customization and intricate details. By using different materials like plastics and metals, it fabricates complex shapes and delicate features that traditional methods struggle to replicate. Industries like automotive, aerospace, and healthcare benefit from its rapid prototyping and on-demand capabilities, reducing production costs and storage needs. Embracing 3D printing drives efficiency and innovation, shaping the future of manufacturing. Discover the vast possibilities unleashed by this transformative technology.

How 3D Printing Transforms Digital Designs

3D printing revolutionizes the process of transforming digital designs into physical objects by creating them layer by layer. This cutting-edge technology allows for the smooth shift from intricate CAD software models to tangible items.

Rapid prototyping is a key benefit of 3D printing, enabling designers to swiftly test and refine their concepts before final production. Unlike traditional manufacturing methods, 3D printing excels in producing custom and complex shapes that were once challenging to achieve.

By building up these objects layer by layer, 3D printers offer a level of customization and detail that's unmatched. The ability to replicate detailed designs accurately in physical form showcases the precision and efficiency of this manufacturing technique.

In diverse industries, the utilization of 3D printing has sparked creativity, innovation, and a new level of customization that was previously unattainable.

Enabling Creation of Complex Objects

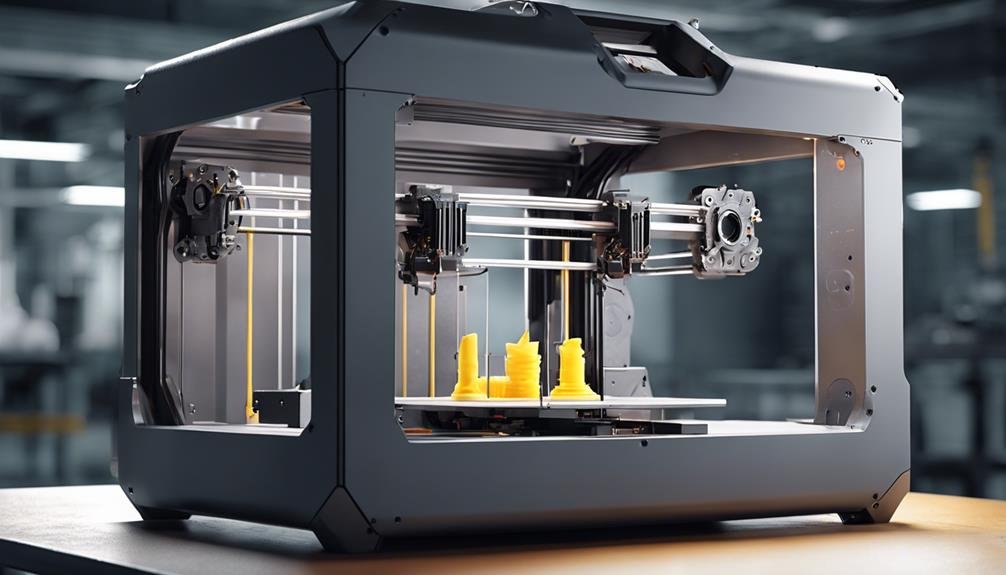

By allowing for the fabrication of geometrically complex designs and structures, 3D printers enable the creation of intricate and detailed objects that traditional manufacturing methods struggle to produce efficiently. These printers utilize different materials such as plastics, resins, and even metals to bring digital designs into the physical world.

The printing process involves layering thin slices of material on top of each other to gradually build up the final object with precision and accuracy.

3D printers revolutionize the creation of intricate parts that would be challenging to manufacture using traditional methods. They create new opportunities for designers and engineers to experiment with shapes and structures previously deemed too complex to produce. The technology allows for the printing of metal parts, opening up possibilities for industries requiring robust and durable components.

Revolutionizing Manufacturing Processes

Revolutionizing manufacturing processes is the core impact of 3D printers, transforming how objects are created from digital designs. These groundbreaking machines enable rapid prototyping, facilitating the quick production of prototypes for testing and validation. By utilizing 3D printers, manufacturers can achieve cost-effective production of intricate and customized parts that traditional manufacturing methods struggle to replicate. The technology streamlines design iterations, allowing for faster modifications and improvements, ultimately reducing the time to market for new products.

| Advantages of 3D Printers | |

|---|---|

| Rapid Prototyping | Cost-effective Production |

| Design Iterations | Reduce Time to Market |

| Impact on Industries | Parts on Demand |

| Storage Costs |

Industries such as automotive, aerospace, and healthcare have been greatly impacted by the capabilities of 3D printing. Manufacturers can now produce parts on demand, saving on storage costs and reducing waste, thus transforming the traditional manufacturing landscape.

Enhancing Precision and Detail

Enhancing precision and detail through 3D printing technology revolutionizes the creation of intricate designs and complex geometric shapes. By utilizing layer-by-layer deposition, 3D printers excel at producing highly detailed prototypes, custom parts, and personalized products with accuracy down to microns.

This process allows for the realization of intricate structures that traditional manufacturing methods struggle to replicate. The ability to capture delicate features and fine textures sets 3D printing apart in the field of manufacturing, enabling the fabrication of items with unparalleled precision.

- 3D printers excel at creating complex geometric shapes

- They enable the production of highly detailed prototypes and custom parts

- The technology allows for the creation of intricate structures and delicate features

In essence, 3D printing offers a level of detail and precision that's vital for industries where intricate designs play a significant role in product development and manufacturing processes.

Utilization Across Various Industries

3D printers find widespread application across different industries, serving critical roles in improving efficiency, innovation, and cost-effectiveness in manufacturing processes. These versatile machines are utilized for rapid prototyping, on-demand production, and cost-effective customization in sectors such as automotive, aerospace, medicine, and consumer products.

Their ability to quickly produce prototypes and final products enables design iterations that lead to better customer-centric solutions. Additionally, 3D printers play a significant role in manufacturing aids, creating components, and even repairing parts in different industries.

The cost-effectiveness of customization through 3D printing reduces storage costs and waste, while also positively impacting the environment. By facilitating on-demand production, these printers streamline processes and boost productivity.

The versatility of 3D printers makes them indispensable tools for businesses looking to innovate, reduce costs, and improve the quality of their products across a wide array of industries.

Driving Rapid Prototyping and Customization

To drive rapid prototyping and customization effectively, consider the flexibility and efficiency that 3D printers offer in tailoring products to specific needs and accelerating design iterations.

- Cost-Effective Small-Batch Production: 3D printers enable the production of small batches of customized products without the need for expensive molds or tooling, reducing manufacturing costs greatly.

- Unique Designs and Personalized Solutions: With 3D printing, intricate and customized designs can be easily created to meet individual requirements, offering personalized solutions that traditional manufacturing methods may struggle to achieve.

- Reduced Time to Market: By allowing for quick design iterations and prototypes, 3D printers speed up the product development process, enabling companies to bring new products to market faster and stay ahead of the competition.

Embracing 3D printing for rapid prototyping and customization not only improves the efficiency of the manufacturing process but also fosters innovation by providing the means to develop unique and tailored products efficiently.

Innovating Design Possibilities

Revolutionizing design processes, a 3D printer enables designers to investigate limitless creative possibilities and push the boundaries of product development. These groundbreaking manufacturing tools open up a domain of pioneering design possibilities by offering rapid prototyping capabilities that allow for quick iteration and testing of different design concepts.

By harnessing the power of 3D printers, designers can effortlessly create customized products that cater to specific needs and preferences, leading to the production of unique and tailored items that traditional manufacturing methods struggle to replicate.

3D printing offers a groundbreaking approach to product development, empowering designers to discover new avenues and challenge conventional design norms. With the ability to fabricate intricate and complex designs with unparalleled precision and accuracy, 3D printers facilitate the creation of one-of-a-kind products that truly stand out in the market.

Frequently Asked Questions

What Is the Point of Having a 3D Printer?

When you have a 3D printer, you open up endless possibilities for creative projects, rapid prototyping, customized products, educational tools, home manufacturing, medical applications, industrial production, DIY projects, architectural modeling, and personalized gifts. It's a game-changer!

What Is the Function of the 3D Printer?

To understand the function of a 3D printer, you must recognize its versatility. From rapid prototyping to custom manufacturing, this technology supports product development, educational tools, medical applications, artistic creations, architectural models, aerospace, jewelry making, and automotive parts.

What Is 3D Printing Mainly Used For?

You mainly use 3D printing for prototyping designs, creating models, and making customized products. It's also handy for rapid manufacturing, medical applications, education projects, artistic creations, architectural models, tool production, and hobbyist projects.

What Is the Basic Use of 3D Printer?

To comprehend the fundamental use of a 3D printer, you can investigate its versatile capabilities in design prototyping, custom manufacturing, rapid prototyping, low volume production, education, art, medicine, aerospace, automotive, and architecture. Its potential is limitless.

Conclusion

To sum up, the purpose of a 3D printer is to transform digital designs into tangible objects, revolutionize manufacturing processes, improve precision, and detail, and drive rapid prototyping and customization. 3D printing has the potential to streamline production, reduce waste, and create more efficient and cost-effective supply chains. Additionally, with the incorporation of realtime 3d printer monitoring, manufacturers can closely monitor the progress and quality of prints, leading to improved workflow and overall efficiency in the manufacturing process. Overall, 3D printing technology continues to advance and has the potential to significantly impact numerous industries in the years to come.

From creating complex objects to innovating design possibilities, 3D printing is a versatile technology that's utilized across different industries.

Its ability to bring ideas to life with speed and accuracy makes it a valuable tool for designers, engineers, and manufacturers alike.

Contents

- 1 How 3D Printing Transforms Digital Designs

- 2 Enabling Creation of Complex Objects

- 3 Revolutionizing Manufacturing Processes

- 4 Enhancing Precision and Detail

- 5 Utilization Across Various Industries

- 6 Driving Rapid Prototyping and Customization

- 7 Innovating Design Possibilities

- 8 Frequently Asked Questions

- 9 Conclusion