In the domain of advanced technology, 3D printers are revolutionizing how food is crafted. Edible materials are utilized, heated for flexibility, and then precisely extruded layer by layer onto a build plate. This additive manufacturing method allows for intricate designs and personalized nutrition. Benefits include culinary innovation, customized meals, and efficient mass production. However, challenges like speed limitations and regulatory hurdles persist. The future holds promises of sustainable protein sources, space exploration integration, and wider culinary advancements. As you delve further, uncover the endless possibilities and ethical considerations shaping the fascinating world of 3D food printing.

How 3D Food Printing Works

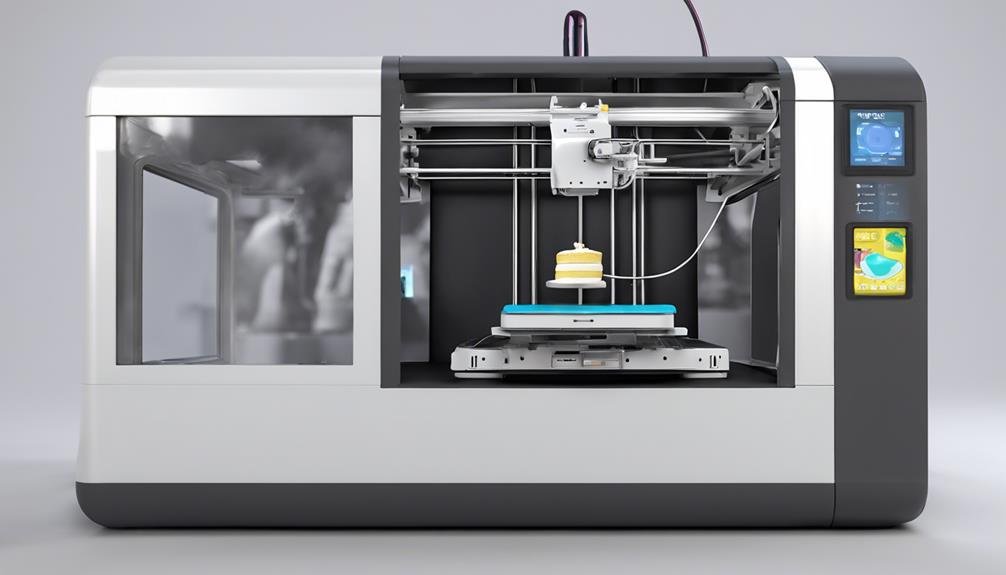

When exploring how 3D food printing works, edible materials and ingredients are used to create food items through an additive manufacturing process. The printer operates by preparing food that's then placed into a canister, heated to achieve malleability, and ultimately extruded onto a build plate layer by layer. This process allows for precise control over the shape, texture, and even nutritional content of the food being created. The beauty of how 3D printed food works lies in its ability to customize meals for individual dietary needs and preferences, making it a promising solution for future culinary innovations. Additionally, by minimizing food waste and utilizing sustainable ingredients, 3D food printing presents potential ecological benefits.

This intricate printing process involves the careful curing of perishable items to set the ingredients, influencing the texture and structure of the final product. The 3D printer follows a preprogrammed recipe to precisely recreate digital designs, enabling customization of shape, flavor, and even nutritional content based on the user's preferences.

The layer-by-layer approach ensures that each component of the food item is meticulously placed, resulting in a detailed and accurate reproduction of the intended design. Understanding the printing process is vital for harnessing the full potential of 3D food printing technology, ensuring the creation of safe, high-quality, and creative food products.

Benefits of 3D Food Printing

Unlocking culinary creativity and efficiency, 3D food printing offers a range of benefits that revolutionize food production. With this technology, you can create customized food items tailored to specific nutritional needs.

Imagine designing unique shapes, structures, and flavors to cater to individual preferences or dietary requirements. From marketing personalized food creations to meeting the precise nutritional demands of different groups, 3D food printing allows for unparalleled control over ingredients.

Moreover, the efficiency of mass production is greatly improved through 3D food printing. The technology minimizes waste and reduces storage requirements, leading to cost-effective and sustainable food manufacturing processes.

Additionally, consistency in culinary creations at scale is ensured, ensuring uniformity in the quality and presentation of food products. By harnessing the power of 3D food printing, you can optimize efficiency, meet diverse nutritional needs, and unlock your creative potential in the culinary world.

Customization and Personalization

Customizing and personalizing food through 3D printing technology allows for precise control over different aspects such as shape, texture, flavor, and nutritional content. With the ability to tailor food items to specific preferences, 3D printing revolutionizes the culinary experience.

Imagine having the power to design a meal perfectly suited to your taste buds and dietary requirements. This level of customization extends beyond mere aesthetics; it explores the domain of creating food that meets individual needs, whether for health reasons or personal preferences.

Moreover, the personalization capabilities of 3D food printing extend to marketing items, enabling businesses to create unique products that resonate with their target audience. By harnessing this technology, food producers can optimize ingredient usage, reduce waste, and improve efficiency in mass production processes.

The precision and consistency offered by personalized 3D printed food products not only cater to individual tastes but also maintain uniformity in culinary creations at scale. The future of food is indeed personalized, thanks to the transformative power of 3D printing.

Impact on Food Industry

Revolutionizing the food industry, 3D food printing offers a groundbreaking approach to customized production and cutting-edge culinary experiences. This additive manufacturing technology has the potential to reshape how food is prepared, distributed, and consumed. By utilizing a food printer, businesses in the food industry can create intricate designs, personalized nutrition options, and unique textures on a mass scale. The efficiency of 3D food printing allows for localized production, reducing transportation costs and minimizing food waste, thus positively impacting sustainability efforts within the food sector. As this technology becomes more commercially available, it is expected to drive a shift from traditional mass manufacturing to more flexible and personalized production lines. In the future, consumers may find 3D food printers as common kitchen appliances, offering them greater control over ingredients and the ability to tailor their meals to specific preferences.

| Food Industry | Impact of 3D Food Printing |

|---|---|

| Customized Production | Enables intricate designs, personalized nutrition, and unique textures |

| Efficiency | Reduces distribution costs and minimizes food waste |

| Shift in Production | Moves towards customized production lines from traditional mass manufacturing |

| Consumer Benefit | Greater control over ingredients and personalized food options |

| Sustainability | Positively impacts sustainability efforts within the food sector |

Challenges and Limitations

Facing challenges and limitations, 3D food printing technology encounters hurdles that impede its widespread adoption and efficiency in the food industry. Maintaining sustainable food practices while meeting food safety standards during the printing process remains a critical challenge.

The speed of printing is limited by the properties of the materials used, resulting in slower processes. Furthermore, ensuring regulatory compliance poses a significant obstacle for the seamless integration of 3D food printing technology into mainstream food production.

Technical issues like nozzle clogging and inconsistent material composition can disrupt the printing process, further complicating its implementation. Moreover, the initial high costs associated with investing in 3D food printing equipment present a limitation in terms of cost-effectiveness.

Overcoming these challenges and limitations is vital for the advancement of 3D food printing technology and its potential to revolutionize the food industry by offering creative solutions for food production and customization.

Future Possibilities and Innovations

In the world of 3D food printing, thrilling advancements and creative possibilities are on the horizon. The integration of 3D printing technology in space exploration is a fascinating direction for the future. Imagine astronauts being able to enjoy freshly printed food products customized to their nutritional needs while on long missions.

Moreover, food tech companies are continually pushing the boundaries of what can be achieved with printed food, exploring sustainable protein sources like insects and plant-based alternatives. This innovation not only addresses the issue of food scarcity but also promotes environmentally friendly practices.

Furthermore, the future holds the promise of 3D printing becoming a common kitchen appliance, with households having the ability to create personalized and nutritious meals effortlessly. The potential for customized products made through 3D printing to become mainstream is exciting, as it could revolutionize the way food products are manufactured and consumed.

As this technology advances, the possibilities for culinary creativity and efficiency are endless.

Ethical and Safety Considerations

Ensuring transparency in ingredient sourcing and upholding food safety standards are critical ethical and safety considerations in the domain of 3D food printing.

Ingredient Sourcing:

It's imperative to trace the sources of ingredients used in 3D food printing to guarantee their quality and safety for consumption.

Regulatory Oversight:

Regulatory bodies play a significant role in monitoring the safety aspects of 3D food printing, including bacterial control and material safety, to safeguard consumer well-being.

Copyright Issues:

Addressing copyright concerns is fundamental when replicating existing food items through 3D printing. Legal guidelines must be established to protect intellectual property rights and prevent unauthorized duplication.

These aspects highlight the intricate balance between innovation and responsibility that the 3D food printing industry must navigate to maintain ethical standards, ensure food safety, comply with regulations, and protect intellectual property.

Frequently Asked Questions

Can a 3D Printer Make Food?

You can experiment with culinary possibilities using a 3D printer, testing out taste, creating personalized creations, and enhancing food presentation. This cutting-edge technology allows for boundless creativity and mastery over ingredients.

Is 3D Printed Meat Healthy?

3D printed meat offers improved nutritional value, catering to specific dietary needs. It's a healthier protein source that avoids additives, ensuring a cleaner product. Consumer acceptance grows as customization options increase. Environmental impact and regulatory considerations remain essential factors.

Is FDM Printing Food Safe?

Printing food using FDM technology guarantees food safety by utilizing FDA-approved materials. Health concerns in additive manufacturing are addressed through proper hygiene and food-grade filaments. Taste testing and culinary applications drive innovation, while regulatory approval guarantees consumer acceptance.

What Is the Difference Between 3D and 4D Food Printing?

In 4D food printing technology, taste and texture can evolve over time, offering unique customization options. This advancement allows for dynamic changes in food properties through stimuli like temperature, moisture, or light, paving the way for exciting future applications.

Conclusion

To sum up, 3D food printing is a groundbreaking technology that has the potential to revolutionize the way we think about food production. With its ability to customize and personalize food, along with its potential impact on the food industry, 3D food printing offers endless possibilities for innovation.

However, there are still challenges and limitations that need to be addressed, along with ethical and safety considerations to be taken into account.

The future of 3D food printing holds exciting opportunities for the food industry.