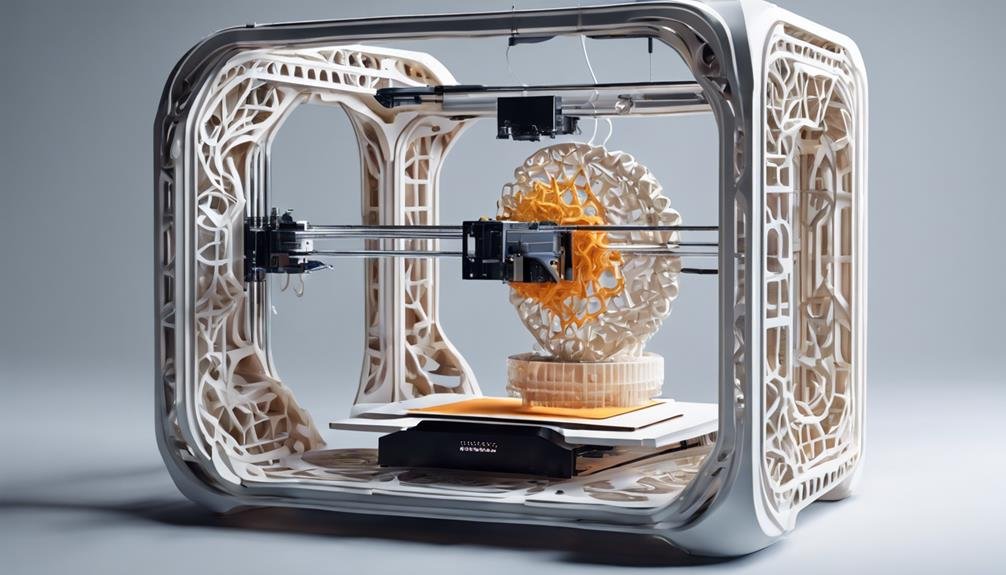

You can create complex objects with intricate designs, moving parts, and interlocking components using a 3D printer, but the possibility of printing anything is limited by the printer's capabilities, the material's properties, and the object's size and complexity. With over 100 materials available, including plastic, metal, and carbon fiber, you can print objects of different sizes, from small trinkets to large structures. However, high-resolution printers are needed for intricate designs, and material suitability is essential. As you delve into the world of 3D printing, you'll uncover the endless possibilities and nuances that come with creating complex objects, and reveal the secrets to tapping into your creative potential.

Printing Limitations and Constraints

Your 3D printing endeavors will inevitably encounter limitations and constraints that can impact the success of your project. One of the primary constraints is size and complexity, as larger objects require industrial-scale printers, while intricate designs demand high-resolution printers.

Moreover, material suitability is a critical factor, as certain materials like metals or ceramics may not be compatible with all 3D printers due to specific printing requirements. Printing speed is another consideration, as it varies depending on the complexity of the object and chosen printing settings. Intricate designs, for instance, take longer to print.

In addition, achieving certain properties like transparency, flexibility, or specific surface finishes can be challenging, depending on the material used. To overcome these limitations, it's crucial to carefully plan your project, considering the capabilities of your printer and the requirements of your design.

Types of 3D Printable Materials

With over 100 materials to choose from, you can print a vast array of objects, from functional tools to artistic creations, using materials like plastic, metal, carbon fiber, and more.

The versatility of 3D printing technology allows for the creation of objects ranging from small toys and gadgets to architectural models and functional tools. You can print with rubber, glass, cardboard, concrete, and even human tissue, making it possible to cater to the unique needs of specific industries like architecture, engineering, medicine, fashion, and music. The purpose of a 3D printer extends beyond mere prototyping; it enables the production of fully functional parts and custom products tailored to individual requirements. This adaptability has revolutionized industries by reducing manufacturing costs, minimizing waste, and accelerating production timelines. As the technology continues to advance, the purpose of a 3D printer becomes increasingly integral to innovative design and sustainable manufacturing practices worldwide.

Customization is a key feature of 3D printing, enabling personalized solutions and the production of bespoke items tailored to individual needs. The continuous development of materials for 3D printing leads to improved capabilities and opens up new possibilities for creating diverse objects.

As the types of materials expand, so do the possibilities for innovation and creativity. With 3D printing, you can bring your imagination to life, creating objects that were previously impossible to produce.

Complexity of Design and Structure

As you delve into the world of 3D printing, you'll find that the technology can tackle intricate designs and structures with remarkable precision. 3D printers can produce complex designs with intricate details, thanks to advancements in printing resolutions.

The level of detail and complexity achievable depends on the type of 3D printer and its resolution. Some 3D printers can even print intricate objects with moving parts or interlocking components. Advanced 3D printing technologies like SLA and SLS can handle highly detailed and complex designs with ease.

However, design complexity can impact the printing time and material usage of the 3D printing process. As you craft your 3D model, you'll need to take into account the complexity of your design, as it will affect the printing time. More complex designs require more printing time, which can increase material usage.

Size and Scale of Printable Objects

You can print objects of varying sizes using 3D printing, from small trinkets and toys to large architectural models and even full-scale buildings, offering a remarkable range of possibilities.

The size limitations of printable objects depend on the specific 3D printer's build volume and the slicing software used to prepare the model for printing. Some 3D printers have build volumes of over 1 cubic meter, allowing for the printing of larger objects like furniture pieces or life-sized sculptures.

However, even with size constraints, creative techniques enable printing objects of considerable scale. For instance, objects larger than the build volume can be printed in sections and assembled post-printing to create even larger items. This means you can print large objects, like a life-sized statue or a functional prototype, by printing individual sections and combining them later.

As a result, the possibilities for 3D printing are vast, and the size of your printable objects is limited only by your imagination and the capabilities of your 3D printer.

Post-Processing and Finishing Techniques

Finishing touches can improve your 3D printed creations from rough drafts to refined masterpieces, and a range of post-processing techniques is available to help you achieve stunning results. You can enhance the surface finish of your prints using techniques like sanding, painting, and polishing.

Additional methods for finishing, such as acetone vapor smoothing for ABS prints or UV curing for resin prints, can further elevate the quality of your prints. Don't forget to remove and clean up support structures used during printing to achieve a smoother final appearance.

You can also apply advanced post-processing options, like electroplating, dyeing, or metal coating, to customize and refine the appearance of your printed objects. Furthermore, techniques like annealing for certain materials or applying coatings can add strength and durability to your 3D printed parts.

Common Applications of 3D Printing

Beyond refining your prints, 3D printing technology has numerous practical applications across a range of industries that can greatly benefit from its unique capabilities. You'll find that common applications of 3D printing include prototyping, product development, and creating customized parts. Industries like automotive, aerospace, healthcare, and fashion extensively utilize 3D printing technology to streamline their manufacturing process.

Rapid prototyping, for instance, enables companies to test and refine their designs quickly and efficiently. This, in turn, reduces production time and costs, making it an attractive solution for businesses. Furthermore, 3D printing allows for the creation of customized parts, which is particularly useful in industries where mass production isn't feasible.

In addition, 3D printing can produce intricate designs, functional prototypes, and even replacement parts, making it an invaluable tool in various industries. As you investigate the world of 3D printing, you'll recognize its potential to transform the manufacturing process and create original consumer goods.

Industrial Uses of Additive Manufacturing

In industrial settings, additive manufacturing technologies, including 3D printing, prove particularly valuable for rapid prototyping and producing complex parts with unprecedented precision and efficiency. Industries like automotive, aerospace, and medical fields benefit greatly from the customization and efficiency of additive manufacturing technologies. This is because 3D printing enables the creation of intricate designs, reducing lead times and material wastage in manufacturing processes.

Here are some key ways industrial uses of additive manufacturing are making a significant impact:

- Rapid prototyping: Additive manufacturing allows for rapid prototyping, reducing lead times and enabling companies to test and refine their designs quickly.

- Efficient design: 3D printing enables the creation of complex geometries and structures that would be impossible to produce with traditional manufacturing methods.

- Customization: Additive manufacturing enables the production of customized components and prototypes, reducing the need for expensive tooling and molds.

- Cost-effective production: Companies can utilize additive manufacturing for cost-effective production of specialized components and prototypes.

Designing for 3D Printing Success

To harness the full potential of 3D printing, you'll need to master the art of designing for success, an adventure that begins with creating or finding a 3D model that's optimized for printing.

You can use software like Blender or Fusion 360 to design your 3D model, which will ultimately be saved as an STL file for printing on popular 3D printer types like Filament (FDM) and Resin printers.

However, designing for 3D printing success involves more than just creating a 3D model. You'll need to slice your model into layers using a slicer like Cura, Bambu Studio, or PrusaSlicer, which will generate g-code for layer-by-layer printing.

Once you've prepared your design, you can transfer it to your 3D printer via USB, SD card, wifi, or cloud service. Popular models like the Creality Ender 3 Pro offer an affordable entry point, but require assembly and proper setup for best results.

Overcoming 3D Printing Challenges

As you delve deeper into the world of 3D printing, you'll inevitably encounter challenges that can make or break your printing experience. These challenges can arise from complex geometries, overhangs, and fine details in your design, making it difficult to achieve a successful print. However, with the right strategies, you can overcome these obstacles and produce high-quality objects.

To overcome 3D printing challenges, consider the following:

- Optimize print settings: Adjust layer heights, infill density, and support structures to guarantee a successful print.

- Use advanced software tools: Utilize features in slicers to address bridging, warping, and adhesion issues.

- Perform regular maintenance: Calibrate and troubleshoot your printer to prevent common issues.

- Select the right manufacturing process: Choose a printing technology that suits your design and material requirements.

Pushing the Boundaries of 3D Printing

You're about to investigate the vast potential of 3D printing, which has already begun transforming industries and pushing the boundaries of innovation. As you dive deeper, you'll realize that using 3D printing, you can create complex geometries and thin layers, used to create intricate structures and objects with precision.

New technologies are emerging, expanding the scope of 3D printing applications. In industries like architecture, engineering, and medicine, 3D printing is being used to create the final products, from prototypes to functional parts. The benefits are numerous, including customization, rapid prototyping, cost-effectiveness, and reduced material wastage.

As you push the boundaries of 3D printing, you'll find that the possibilities are endless. From printing organs for medical research to creating bespoke fashion accessories, the technology is revolutionizing the way we design, produce, and interact with objects. With ongoing advancements in materials and integration with IoT and AI, the future of 3D printing looks brighter than ever.

Frequently Asked Questions

What Cannot Be 3D Printed?

You can't 3D print living tissues, complex organs, or functional magnets, as they require biological or magnetic properties that current 3D printing tech can't replicate, and large structures or delicate fabrics that exceed printer size or material limitations.

What Am I Not Allowed to 3D Print?

As you venture into 3D printing, you're not allowed to print copyrighted materials, items that infringe on patents, or objects that violate safety restrictions or moral obligations, ensuring you respect legal boundaries and ethical standards.

What Is 3D Printing Not Good For?

You'll find 3D printing isn't ideal for tasks that require strict food safety regulations, as it may compromise material purity. Moreover, material limitations, post-processing demands, labor laws, and environmental impact concerns can also hinder its effectiveness in certain applications.

Can 3D Printing Make Everything?

As you investigate the possibilities of 3D printing, you'll find that, while it offers limitless possibilities, printing barriers and material constraints still exist, but design freedom and future applications are vast, and it can make almost everything.

Conclusion

As you've delved into the world of 3D printing, you've noticed that while the possibilities are vast, there are limitations to what can be printed. From material constraints to design complexities, each aspect affects the final product.

However, by understanding these factors and designing with 3D printing in mind, you can overcome challenges and push the boundaries of this cutting-edge technology.

By mastering the intricacies of 3D printing, you'll tap into its full potential and bring your most ambitious projects to life.

Contents

- 1 Printing Limitations and Constraints

- 2 Types of 3D Printable Materials

- 3 Complexity of Design and Structure

- 4 Size and Scale of Printable Objects

- 5 Post-Processing and Finishing Techniques

- 6 Common Applications of 3D Printing

- 7 Industrial Uses of Additive Manufacturing

- 8 Designing for 3D Printing Success

- 9 Overcoming 3D Printing Challenges

- 10 Pushing the Boundaries of 3D Printing

- 11 Frequently Asked Questions

- 12 Conclusion