When choosing between an enclosed and open 3D printer, you'll need to weigh the pros and cons. Enclosed printers prioritize safety, maintaining stable temperatures to prevent burns and injuries, while open printers lack this control. Enclosed printers also offer better temperature control, reduced warping, and quieter operation, making them ideal for ABS and large parts. However, they're generally more expensive and require more maintenance. Open printers, on the other hand, are more affordable and compact, but may compromise on print quality. As you assess your needs, you'll explore more about the intricacies of 3D printing and how to make an informed decision.

Enclosed Printers: Safety First

When working with 3D printers, especially in environments where children are present, enclosed printers offer an important safety net by containing the high temperatures of nozzles and beds, thereby preventing accidental burns and injuries.

As you delve into the world of 3D printing, it's vital to prioritize safety, and fully enclosed printers provide that extra layer of protection. You'll appreciate the added security when printing ABS, which can be particularly sensitive. The enclosed design helps maintain a stable print environment, reducing warping and airflow interference, resulting in better print quality.

With an enclosed printer, you can expect consistent output quality, even when working with specialty materials like nylon. By containing the heat and minimizing external factors, you'll achieve better structural integrity, particularly beneficial for large parts.

As you print, you'll notice the improved quality and accuracy, thanks to the controlled environment. With an enclosed printer, you can focus on perfecting your designs, knowing the safety aspect is taken care of.

Temperature Control Matters

Maintaining precise temperature control is crucial in 3D printing, and enclosed printers take the lead in this regard, providing a stable environment that guarantees consistent print quality.

As you delve into the world of 3D printing, you'll find that temperature control is pivotal for producing high-quality prints. Enclosed printers excel in this area, trapping heat and maintaining a consistent temperature, ideal for materials like ABS that require a stable environment to prevent curling.

In contrast, open 3D printers lack temperature stability, requiring environmental testing for consistent print quality. While open printers like the Lulzbot TAZ 5 can handle temperature swings, they may benefit from enclosures for more stable printing.

When printing larger parts, precise temperature control becomes even more critical, and enclosed printers prove to be the better choice. While an open 3D printer might be good enough for small prints, it's important to consider the limitations when working with larger, more complex projects.

Warping and Airflow Issues

As you work with materials like ABS, you'll notice that warping issues are greatly reduced in enclosed printers, which maintain a stable print environment that prevents temperature fluctuations and air currents from ruining your prints. This controlled environment guarantees that your print bed leveling is more precise, and you can achieve enhanced material compatibility.

Additionally, enclosed printers minimize the impact of external factors on print quality, allowing you to focus on fine-tuning your print settings and material selection. In contrast, open printers are more prone to airflow interference, leading to inconsistencies in print quality and adhesion. This can result in warped or failed prints, especially when working with temperature-sensitive materials.

Quiet Operation Advantage

By switching to an enclosed 3D printer, you'll immediately notice a significant reduction in noise levels, creating a more peaceful work environment that's perfect for office or desktop settings. This quiet operation advantage is a major benefit of enclosed printers, making them an ideal choice for shared spaces. The enclosure helps to minimize the disruptive noise often associated with 3D printing processes, providing a quieter experience for you and those around you.

With enclosed printers, you can enjoy noise control and peaceful printing, which is particularly crucial in environments where distractions need to be kept to a minimum. The quiet workspace created by enclosed printers is conducive to productivity and focus, allowing you to work efficiently without interruptions.

Moreover, the reduced noise levels make it easier to collaborate with colleagues or work in close proximity to others. In essence, the quiet operation of enclosed 3D printers is a significant advantage over open printers, providing a more comfortable and distraction-free printing experience.

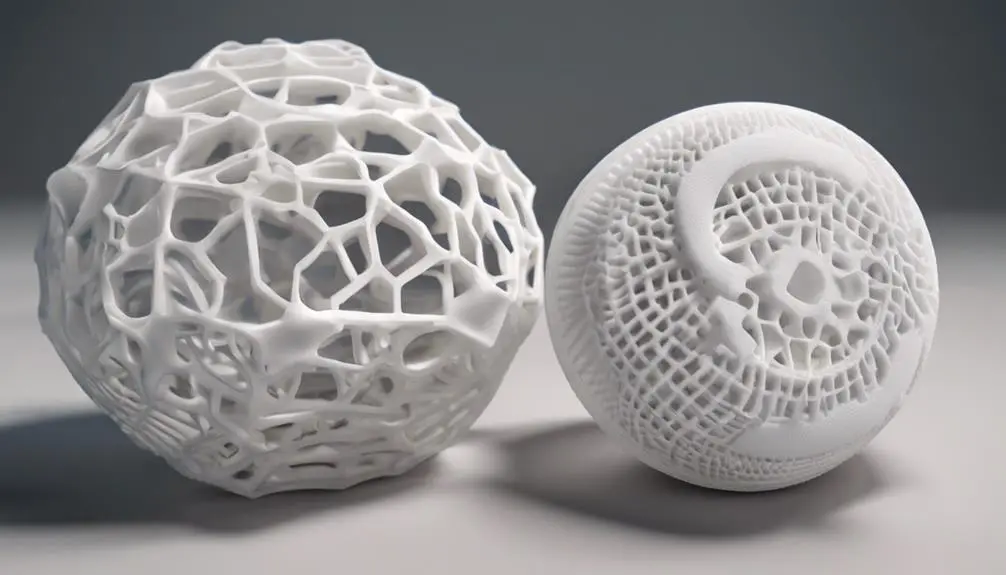

Print Quality Comparison

You'll notice a significant difference in print quality between enclosed and open 3D printers, with enclosed printers consistently producing higher-quality prints due to their ability to maintain a stable temperature environment. This importance is essential for printing with challenging materials like ABS, which requires a consistent temperature to maintain structural integrity. In contrast, open printers may struggle with intricate details and large prints due to temperature fluctuations, leading to warping and poor layer adhesion.

| Printer Type | Material Compatibility | Layer Adhesion | Print Durability |

|---|---|---|---|

| Enclosed | Excellent for ABS and large parts | Strong, consistent layers | High, with minimal warping |

| Open | Limited to PLA and small parts | Weak, prone to delamination | Low, with warping and cracking |

| Hybrid | Good for most materials, but may struggle with large parts | Good, but may vary | Medium, with some warping |

Enclosed printers are recommended for ABS and large parts to maintain structural integrity, while open printers may struggle with these types of prints. The print quality differences between enclosed and open printers are noticeable, especially with challenging materials like ABS. By understanding the strengths and weaknesses of each type of printer, you can choose the right one for your specific needs and achieve high-quality prints.

Closed Vs Open Design

Your printer's design plays a crucial role in determining the quality of your prints, and the choice between a closed and open design has significant implications for temperature stability, fume control, and general performance.

When comparing designs, enclosed printers offer better temperature stability and fume control, making them ideal for printing high-temp materials like ABS. This design guarantees consistent print quality, whereas open printers like the Lulzbot TAZ 5 may require environmental testing to achieve similar results.

With regards to material compatibility, enclosed printers provide a more stable environment for printing sensitive materials. Ventilation concerns are also addressed in enclosed designs, which operate quieter and maintain a more stable print environment.

However, open designs may appeal to users who prioritize print speed and are willing to compromise on environmental control. Ultimately, user preferences and market trends will dictate the choice between closed and open designs, but it's important to weigh the implications of each design on print quality and material compatibility.

Upgrade and Maintenance Ease

As you weigh the benefits of enclosed versus open designs, you'll find that maintenance and upgrade requirements can be a significant factor in your decision, with open printers like the Lulzbot TAZ 5 offering a distinct advantage in this regard.

Maintenance benefits are important to consider, with open printers providing effortless maintenance, saving you time and effort. In contrast, enclosed printers often require disassembly, which can be a challenging task, leading to disassembly drawbacks and upgrade complexity.

With open printers, you can access internal parts easily, making upgrades a breeze. This upgrade accessibility allows for time-saving upgrades, reducing the time spent on maintenance. Open printers offer more flexibility, making it easier to swap out components or add new ones. This flexibility translates to reduced downtime, getting you back to printing sooner.

Cost and Space Considerations

Considering your budget and available workspace, cost and space considerations can greatly influence your decision between an enclosed and open 3D printer. Enclosed printers, with their added features and components, tend to be more expensive than open printers. On the other hand, open printers are typically more compact, making them a great option for smaller workspaces.

Here's a breakdown of the cost and space considerations:

| Feature | Enclosed 3D Printer | Open 3D Printer |

|---|---|---|

| Cost | Generally more expensive | Less expensive |

| Space | Larger footprint | Compact design |

| DIY Enclosure | Not necessary | Cost-efficient option |

| Material Savings | No material savings | Material savings possible |

| Maintenance | May require more maintenance | Less maintenance required |

When it comes to cost efficiency, a DIY enclosure for an open 3D printer can be a more affordable option. Open printers offer space optimization with their compact design, making them ideal for smaller workspaces. Ultimately, your decision will depend on your specific needs and priorities.

Frequently Asked Questions

Is an Enclosed 3D Printer Better?

You'll achieve superior print quality with an enclosed 3D printer, which provides thermal stability, reduces noise, and improves layer adhesion, ensuring consistent results, especially with temperature-sensitive materials like ABS.

Do 3D Printers Need to Be Enclosed?

You don't necessarily need an enclosure, but it helps with warping issues on the print bed and mitigates environmental factors that affect print quality, ensuring consistent results in a controlled environment.

What Are the Benefits of a 3D Printer Enclosure?

You'll enjoy improved print quality and reduced warping with an enclosure, thanks to precise temperature control. Plus, you'll appreciate the noise reduction and air filtration benefits, creating a healthier and more comfortable printing experience.

Do Enclosed 3D Printers Need Ventilation?

You don't typically need ventilation with enclosed 3D printers, but it's still crucial to take into account air flow and safety protocols, particularly when working with materials that necessitate fume extraction to guarantee a safe printing environment.

Conclusion

When considering the pros and cons of enclosed vs open 3D printers, keep in mind that each design serves a specific purpose.

If safety, temperature control, and quiet operation are your top priorities, an enclosed printer is the way to go.

However, if you're on a budget, have limited space, and don't mind tinkering, an open printer might be the better fit.

Ultimately, consider your specific needs and preferences to make an informed decision that suits your 3D printing goals.