You're wondering how long it takes to 3D print a small object. Well, the answer depends on different factors, including the object's complexity, layer height and thickness, and the type of 3D printer used. Finer details and intricate designs increase printing time, while thicker layers and larger nozzles can speed up the process. The object's size and shape also impact printing duration, with smaller, simpler shapes being quicker to print. Understanding these factors is important to optimizing your 3D printing experience, and there's more to discover on how to efficiently print your small object.

Understanding 3D Printing Time Factors

When you're getting ready to 3D print a small object, it's important to consider the key factors that affect the printing time, as they can greatly impact the duration of the process. The complexity of your design, layer height, and printer settings all play a major role in determining the printing time.

For instance, a higher layer height can reduce printing time, but may compromise on detail and resolution. On the other hand, using faster printing technologies and optimizing printer settings can greatly reduce the printing time.

Moreover, the type of slicing software used can also impact the printing process. Additionally, post-processing tasks such as cleaning, support removal, and finishing can add extra time to the printing process.

Consulting with 3D printing experts can provide accurate time estimates and help expedite the printing process. By understanding these factors, you can better plan and prepare for the time required to 3D print your small object. By doing so, you can ensure a smoother and more efficient printing process.

Complexity of Design Matters

The complexity of your design is an important factor in determining the 3D printing time. A small object with intricate features will certainly take longer to print than a simple one. This is because intricate details and fine features in the design add to the printing duration.

Factors like curves, overhangs, and internal structures also contribute to the printing time of small objects.

Here are some key points to keep in mind:

- Intricate designs take longer: A small object with intricate patterns or structures will take longer to print compared to a basic shape.

- Fine features add time: The more fine features your design has, the longer it will take to print.

- Curves and overhangs matter: These design elements can increase the printing time of your small object.

- Internal structures impact printing time: The complexity of internal structures can have a notable effect on the 3D printing time required.

3D Printer Type and Speed

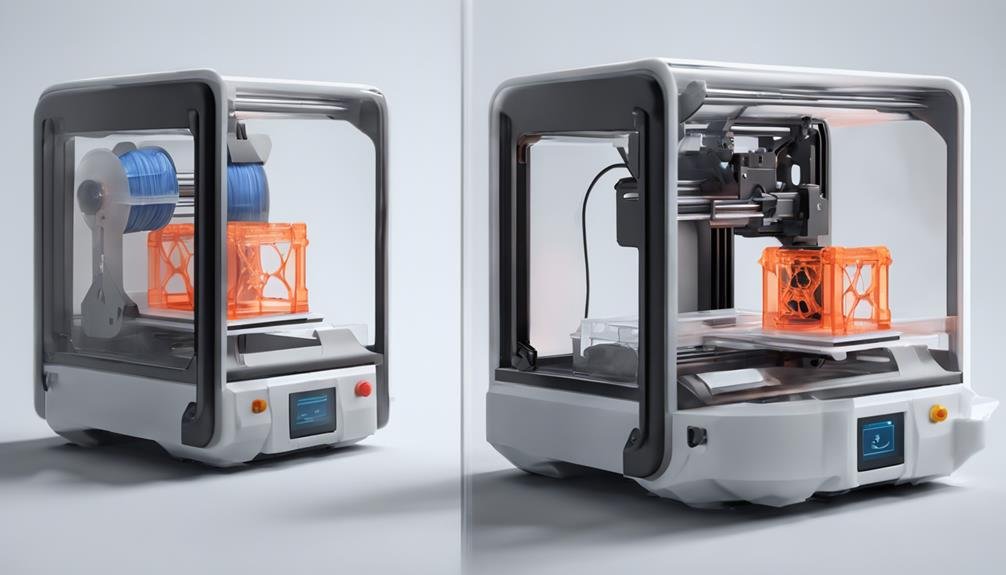

You'll find that the 3D printer type you're using greatly impacts the speed at which you can produce small objects. The type of 3D printer you use can have a significant effect on your printing speed, and faster printers usually come with a higher price tag. Different printing technologies, such as FFF, SLA, SLS, and DLP, have varying speeds for small object production.

Factors like nozzle size, print head size, and distance from the print bed also play an important role in determining your printing speed. Understanding the capabilities and settings of your 3D printer is vital for optimizing the time taken to print small objects. To enhance your time, you need to take into account your print settings, including the nozzle size, which affects the printing speed and resolution.

Layer Height and Thickness

Adjusting your layer height and thickness is crucial to finding the perfect balance between print quality and speed, as it directly affects the time it takes to 3D print a small object. You'll need to take into account the complexity of your object and the level of detail required.

Here are some key points to bear in mind:

- Finer details, longer print times: If your object has intricate details, you may need to utilize a smaller layer height, such as 0.1mm, which will extend the total print duration.

- Thicker layers, faster prints: Conversely, using a thicker layer height, like 0.3mm, can greatly reduce printing time for small objects.

- Balancing quality and speed: Adjusting layer thickness based on the object's size and complexity can help you discover the ideal balance between print quality and speed.

- Total printing time impact: Keep in mind that layer height directly impacts the number of layers needed to complete a print, influencing the total printing time for small objects.

Post-Printing Processing Time

After hitting the print button, you're still a few steps away from holding your finished small object, as post-printing processing time can add a significant chunk to the entire production time. The time spent on post-printing processing can range from a few minutes for basic cleaning to several hours for extensive sanding, painting, or assembly, depending on the material type, print quality, and desired finish.

For instance, post-curing resin prints may add a few hours to the total printing time for small objects. Moreover, functional testing and final touch-ups can also contribute to the post-printing processing time.

To minimize the production time, it's crucial to adopt efficient post-processing techniques that streamline the entire process. By understanding the factors that affect post-printing processing time, you can better plan and manage your 3D printing projects, ensuring that your small objects are printed and ready for use in the shortest time possible.

Object Size and Shape Impact

Within a few minutes to a few hours, the 3D printing process can churn out a small object, but the size and shape of the object greatly impact the duration. You'll notice that the printing time varies considerably depending on the object's size and shape.

Here are some key factors to keep in mind:

- Smaller objects take less time: Objects with a smaller volume require fewer layers, resulting in a shorter printing time.

- Complex shapes take longer: Intricate designs and complex shapes require more layers and printing time, even if the object is small.

- Object height matters: Taller objects take longer to print due to the increased volume and layer count.

- Simple shapes are quicker: Objects with minimal details and simple shapes can be completed in under an hour.

Keep in mind that the object's shape and size have a direct impact on the printing time. A small object with intricate designs will take longer to print than a simple, small object with minimal details.

Material and Quality Effects

As you navigate the 3D printing process, you'll find that the type of material you choose and the quality settings you select can greatly impact the time it takes to print a small object. The material choice, for instance, can greatly influence the printing speed. Some materials, like PLA, print faster than others, like metal-filled filaments.

| Material | Printing Speed |

|---|---|

| PLA | Fast |

| ABS | Medium |

| Metal-filled | Slow |

In addition to material choice, the quality settings you select also play a vital role in determining the printing duration. Higher quality prints typically take longer to complete due to finer details and increased resolution settings. Factors like layer height and infill density, chosen for better quality, can extend the printing time for small objects. Post-processing steps for enhancing the quality of small 3D printed objects can add to the overall printing time. Balancing material choice and quality settings is necessary to optimizing the printing time for small objects while ensuring satisfactory results. By understanding the impact of material and quality effects, you can make informed decisions to achieve the best possible outcome for your 3D printing projects.

Optimizing 3D Printing Speed

By adjusting your printer's settings, you can greatly reduce the time it takes to 3D print small objects. Optimizing your printing speed can be achieved through different techniques, allowing you to produce small objects efficiently.

Here are some ways to optimize your 3D printing speed:

- Scale down the object size: Reducing the size of the object can greatly decrease the printing time required.

- Use larger nozzle sizes: Printing with larger nozzles can speed up the process without compromising on quality.

- Print multiple objects simultaneously: Printing multiple small objects at once can be more time-efficient than printing them one by one.

- Optimize slicing software settings: Efficiently optimizing slicing software settings for small objects can lead to faster and more precise 3D prints.

Frequently Asked Questions

How Long Does It Take to 3D Print Objects?

When you 3D print objects, factors like print speed, layer thickness, material cost, and fused deposition affect production time, which depends on object complexity, printing volume, machine capacity, and print priority.

Can You 3D Print Tiny Things?

You can 3D print incredibly tiny things, like microscopic details, tiny mechanisms, small robots, delicate structures, intricate designs, miniature art, tiny tools, small implants, and microscopic models, thanks to precise engineering and advanced 3D printing technologies.

How Fast Can You 3D Print?

You can 3D print quickly by adjusting print speed, layer thickness, and material flow, while considering nozzle size, printing mode, layer adhesion, support material, and print quality, all dependent on machine type and printing cost.

How Long Does It Take to Cure a Small 3D Print?

When you're waiting for your small 3D print to cure, the cure time depends on factors like material type, layer thickness, and temperature control, with resin quality and UV exposure affecting the post-curing process.

Conclusion

As you've seen, the time it takes to 3D print a small object depends on different factors, including the design's complexity, printer type, layer height, and material quality.

By understanding these aspects, you can optimize your printing process and create objects efficiently.

By fine-tuning your settings and choosing the right materials, you'll be able to produce high-quality objects in a reasonable amount of time, making 3D printing a valuable tool for prototyping, modeling, and production.