You're about to realize that 3D printed metal parts can exhibit strength up to three times that of conventionally made steels, thanks to the unique process of additive manufacturing that allows for precise control over material structure. The rapid cooling process in 3D printing contributes to material strength and ductility, while the microscopic structure of 3D printed stainless steel features tightly packed alloy grains and strong boundaries. With controlled temperature shifts influencing crystal structure and mechanical properties, you'll find that strong, flexible, and ductile metals from 3D printing provide cost savings and manufacturing flexibility. Now, delve into the intricacies of 3D printing technology and uncover more about its applications and potential.

Mechanical Properties of 3D Printed Metal

You'll be amazed to learn that 3D printed metal parts can exhibit astonishing mechanical properties, boasting strength up to three times that of conventionally made steels. This remarkable strength is attributed to the unique process of 3D printing, which allows for precise control over the material structure.

In the case of stainless steel, the dense layers with tiny cell wall-like structures help prevent fractures, making it incredibly resilient. Moreover, the rapid cooling processes involved in 3D printing contribute to the material's strength and ductility. The result is a metal that remains flexible and tough, making it an attractive option for different applications.

Research published in Nature Materials has confirmed these findings, generating excitement in the field. As you explore further into the world of 3D printed metals, you'll uncover the intricate relationships between processing conditions, microstructure, and mechanical properties. By understanding these relationships, you can unleash the full potential of 3D printed metal and harness its exceptional strength and ductility.

Advantages Over Traditional Manufacturing

By capitalizing on the unique advantages of additive manufacturing, you can create complex geometries and internal structures that would be impossible or impractical to produce with traditional manufacturing methods. This freedom in design enables you to print parts with intricate features, such as lattice structures or honeycomb patterns, which can reduce material usage while maintaining exceptional strength.

Moreover, additive manufacturing allows for the creation of complex parts with varying material properties, such as combining different metals or incorporating functional materials. With 3D printing, you can also produce parts with reduced material waste, as the printing process only adds material as needed. This results in significant cost savings and reduced environmental impact.

In addition, the ability to rapidly prototype and test new designs enables you to iterate and refine your parts more quickly, streamlining the product development process. By embracing the advantages of additive manufacturing, you can discover new possibilities for creative product design and production.

Industrial Applications of Strong Metals

In critical industries like aerospace, maritime, and energy, 3D printed strong metals, such as 17-4 precipitation hardening stainless steel, are revolutionizing the production of crucial components. You'll find these metals in applications where strength, corrosion resistance, and precision are paramount.

| Industry | Component | Benefit |

|---|---|---|

| Aerospace | Turbine blades | Weight reduction, increased fuel efficiency |

| Maritime | Propeller shafts | Corrosion resistance, reduced maintenance |

| Energy | Nuclear reactor components | Enhanced safety, longer lifespan |

The additive manufacturing process involves precise control of alloy composition to secure consistent martensitic structure and strength. This results in strong, flexible, and ductile metals, making them ideal for demanding industrial applications. For instance, 3D printed stainless steels are up to three times stronger than conventionally made steels, thanks to dense layers and precise control of structure. The benefits are undeniable: cost savings, increased manufacturing flexibility, and access to complex geometries. As 3D printing technology advances, you can expect to see even more inventive industrial applications of strong metals.

The Role of Rapid Cooling in Strength

Rapid cooling during 3D metal printing processes is vital for enhancing strength and durability, as it allows for precise control over the metal's crystal structure and mechanical properties.

When you're printing metal, the cooling rate can be extremely high, leading to unique strength properties that wouldn't be possible with traditional manufacturing methods.

By managing the cooling process, you can influence the metal's crystal structure and mechanical properties, resulting in stronger, more durable materials.

Understanding and managing rapid temperature shifts during printing is important for achieving the desired material strength.

The rapid cooling process in metal 3D printing helps create dense structures with improved mechanical properties, making it a fundamental step in producing strong, reliable parts.

Microscopic Structure and Ductility

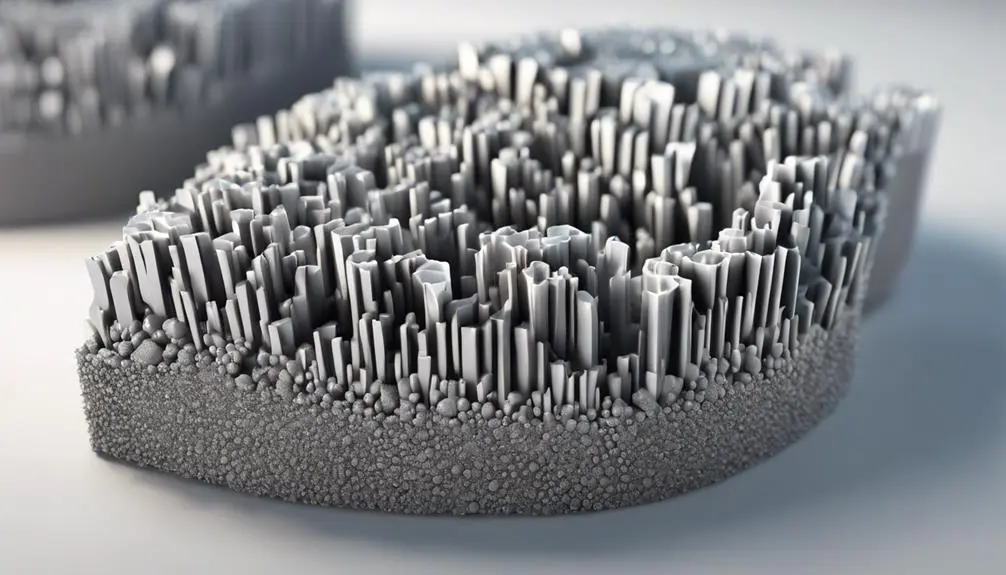

When you investigate the microscopic structure of 3D printed stainless steel, you'll find that its tightly packed alloy grains and strong boundaries contribute to its remarkable strength.

At the microscopic level, the complex arrangement of layers, featuring tiny cell wall-like structures, boosts the material's overall strength and prevents fractures. This is an important aspect of materials science, as it directly affects the final product's properties.

The dense layers produced through 3D printing allow for superior strength, making it up to three times stronger than conventionally made steels.

What's more, the material remains ductile despite its increased strength, making it suitable for applications where both strength and flexibility are required. This unique combination of properties is made possible by the precise control of the cooling process and material structure during 3D printing, ensuring the desired strength and ductility of the final stainless steel product.

As you explore further into the microscopic structure of 3D printed stainless steel, you'll gain a deeper appreciation for the intricate balance of properties that make it such a remarkable material.

Future of 3D Printed Metal Production

As you consider the possibilities of 3D printed metal production, it's clear that this technology is poised to revolutionize industries ranging from aerospace to healthcare.

Printing metal parts layer by layer, using layers of metal powder, allows for the creation of complex shapes and structures that would be impossible to produce using traditional manufacturing methods. This process enables the production of parts that use inventive geometries, reducing weight while maintaining strength.

As the technology advances, you can expect to see widespread adoption in industries where strength, flexibility, and precision are paramount. In the near future, 3D printed metal production will enable the creation of complex components for rocket engines, biomedical implants, and other critical applications.

With the ability to produce parts that are up to three times stronger than conventionally made steels, while retaining ductility, the possibilities are endless.

As the industry continues to evolve, you can expect to see new and imaginative applications emerge, further solidifying the role of 3D printed metal production in shaping the future of manufacturing.

Frequently Asked Questions

Is 3D Printed Metal as Strong as Forged?

You're wondering if 3D printed metal is as strong as forged? Well, it's possible, depending on factors like crystalline structure, grain size, thermal treatment, mechanical properties, and alloy composition, which all impact its general strength.

What Are the Disadvantages of 3D Metal Printing?

When you venture into 3D metal printing, you'll face material limitations, post-processing challenges, and printing defects, which can be costly and time-consuming to overcome, adding to the general cost constraints and support removal hassles.

What Is the Strongest Material You Can 3D Print?

You can 3D print incredibly strong materials, leveraging advanced printing techniques to optimize layer strength and bonding methods. Top material options include industrial-grade thermoplastics like polycarbonate, ABS, and nylon, offering exceptional strength and durability.

How Strong Are Metal Printed Parts?

When you 3D print metal parts, you're achieving impressive material properties, ensuring exceptional structural integrity, high load capacity, and remarkable tensile strength, while also boasting excellent fatigue resistance, making them suitable for demanding applications.

Conclusion

As you've seen, 3D printed metal's strength is rooted in its mechanical properties, which surpass traditional manufacturing in many ways.

Industrial applications are vast, from aerospace to automotive, thanks to rapid cooling's role in enhancing strength.

Microscopic structure and ductility also play an essential role.

As the field continues to evolve, you can expect to see further innovations in 3D printed metal production, leading to even stronger, more efficient, and complex structures.