When troubleshooting common 3D print issues, you're likely to encounter problems like dimensional inaccuracies, poor bridging, and inconsistent extrusion, which can be caused by different factors. Bed adhesion problems, often due to an uneven or warped build plate, can lead to failed prints. Extrusion issues, such as under or over extrusion, can be resolved through proper calibration and maintenance. Filament feed problems, like clogged nozzles, can be prevented with proper tension and alignment. In conclusion, warped or curved prints can be minimized with proper bed leveling, heated beds, and adjusting print settings. As you investigate these issues, you'll uncover more nuances to optimize your 3D printing process.

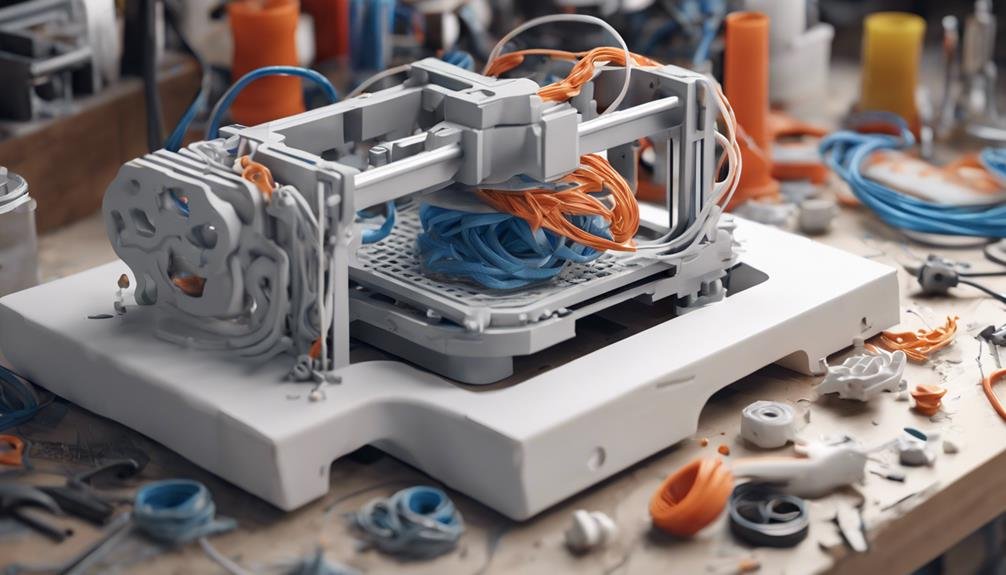

Common 3D Print Issues

You'll likely encounter several common 3D print issues that can affect the quality and functionality of your printed parts, including dimensional inaccuracies, poor bridging, inconsistent extrusion, warping, and zits or blobs. These issues can greatly impact the general quality and functionality of your printed parts, making it vital to identify and address them promptly.

One critical factor to take into account is the build plate, which serves as the foundation for your print. A well-calibrated build plate is pivotal for achieving accurate prints. However, a warped or uneven build plate can lead to poor adhesion, resulting in prints that lift off the plate or exhibit uneven surfaces.

To mitigate this, make sure your build plate is level, clean, and properly calibrated before each print. Regular maintenance, such as cleaning and lubricating the build plate, can also help prevent common 3D print issues.

Bed Adhesion Problems

Proper bed adhesion is important to prevent warping and shifting during the printing process, and it's critical to get it right from the start.

As you prepare to print, you need to make sure that your print bed is ready for excellent adhesion. The type of filament you're using plays a significant role in determining the ideal bed temperature. For instance, ABS filament typically requires a heated bed set to around 90-110°C, while PLA can be printed on a heated bed at 60-70°C.

To improve bed adhesion, you can use techniques like brims, rafts, or adhesive sprays, depending on the type of filament you're working with. It's also important to ensure the print bed is level and clean before starting a print.

A dirty or uneven print bed can lead to poor adhesion, resulting in warping or shifting during the printing process. By taking these factors into account, you can achieve better bed adhesion and produce high-quality prints.

Extrusion Issues Explained

While achieving good bed adhesion sets the stage for a successful print, inconsistent filament flow from the nozzle can quickly derail your efforts and lead to a range of extrusion issues. As you print, you expect a consistent flow of filament, but sometimes this doesn't happen, causing under extrusion, over extrusion, or even clogs in the nozzle.

These extrusion issues can lead to poor print quality, failed prints, and frustration. To avoid these problems, it's vital to calibrate your extrusion settings correctly and maintain a clean nozzle. Using high-quality filament also helps prevent extrusion issues.

When you encounter extrusion problems, troubleshooting is important to get back on track. By identifying and resolving the root cause of the issue, you can achieve successful prints with accurate dimensions and smooth surfaces. Remember, extrusion issues can be prevented with proper calibration, maintenance, and quality filament.

Filament Feed Problems

Checking for tangled or stripped filament in the extruder mechanism can lead to filament feed problems, causing your print to pause or remain incomplete. When this occurs, it's important to identify the root cause to prevent further issues. Filament feed problems can be frustrating, but they're often preventable with proper maintenance and troubleshooting.

Here are some common causes of filament feed problems:

- Clogged nozzles: Make sure to regularly clean your nozzles to prevent blockages.

- Proper tension on the filament: Ensure the filament is properly seated and not too tight or loose.

- Aligned extruder gears: Double-check that your extruder gears are properly aligned to prevent jams.

- Quality filament: Use high-quality filament that's less prone to tangling or stripping.

Warped or Curved Prints

Having mastered the art of troubleshooting filament feed problems, you're now likely to encounter another common issue: warped or curved prints, which can be just as frustrating, especially when you've invested time and resources into a print job.

Warped prints occur due to uneven cooling, leading to stress and deformation in the material. To prevent warping, make sure proper bed leveling, as an unleveled bed can cause uneven cooling and stress on the print. Using a heated bed for certain materials like ABS can also help. Moreover, consider using a brim or raft to improve adhesion to the bed.

Adjusting print settings such as bed temperature, enclosure, and cooling fan can help reduce or eliminate warping. Additionally, drafts in the printing environment can cause warping, so consider optimizing the printing location for better results.

Layer Shifting and Misalignments

You'll likely encounter layer shifting and misalignments in your 3D printing experience, which can be frustrating and detrimental to your print's quality. Layer shifting occurs when the printer's mechanical components or software settings are misaligned, causing the print to become skewed or misshapen. This issue can be caused by loose belts or pulleys, incorrect slicer settings, or corrupted GCODE files.

To troubleshoot layer shifting, you should:

- Check and adjust printer settings, such as print temperature, to guarantee peak performance.

- Verify that the printer's mechanical components, like belts and pulleys, are properly tightened and calibrated.

- Recalibrate the printer to ensure proper alignment and accuracy.

- Review and correct slicer settings and GCODE files to prevent software-related issues.

Regular maintenance, including checking belt tension and ensuring proper calibration, can help prevent layer shifting.

Nozzle Clogs and Blockages

After confirming your printer's mechanical components are in check, it's time to focus on another critical aspect of 3D printing: maintaining a clean and clear nozzle, as nozzle clogs and blockages can silently sabotage your prints.

These common issues can disrupt filament flow, leading to under extrusion or failed prints. You'll want to regularly clean your nozzle to remove debris, dirt, or old filament residue that can cause clogs. Using quality filament can also help prevent blockages.

Furthermore, heat creep can contribute to nozzle blockages, affecting print quality. If you do encounter a clog, troubleshooting involves unclogging, adjusting temperatures, or replacing the nozzle if necessary.

To prevent clogs, make it a habit to inspect your nozzle regularly and perform routine maintenance. By doing so, you'll minimize the risk of print failures and ensure a smooth, consistent print process.

Weak Infill and Delamination

Tune your printer settings to address weak infill and delamination, two common issues that can leave your 3D prints fragile and prone to layer separation. Weak infill occurs when the interior structure of a 3D print lacks strength and density, making it prone to breaking or cracking.

Delamination, on the other hand, refers to layers of a print separating or not bonding properly. To tackle these issues, you'll need to adjust your printer settings and ensure proper bed leveling.

Here are some key adjustments to make:

- Increase the infill density and adjust the pattern to improve strength and prevent delamination

- Experiment with different print temperatures to find the best setting for your filament

- Verify proper calibration of your printer settings to prevent layer shifting and delamination

- Use high-quality filament that's designed for 3D printing to minimize the risk of weak infill and delamination

Frequently Asked Questions

What Went Wrong With My 3D Print?

When you ask "what went wrong with my 3D print?", start by examining the print itself – check for visible defects, layer inconsistencies, or material issues, then review your settings and maintenance to identify the root cause of the problem.

How Do I Get Rid of D Print?

You're stuck in Post Print Anxiety, feeling frustrated and defeated. Take a deep breath, acknowledge your emotions, and remind yourself that it's just plastic. Let go of perfection, and focus on what you can learn from the experience to move forward.

What Is the Biggest Problem With 3D Printing?

You'll likely find that the biggest problem with 3D printing is material limitations, as the available materials often lack durability, strength, or aesthetic appeal, impeding the general quality and functionality of your prints.

What Are Common Fails in a 3D Printer?

When you're 3D printing, you'll encounter common fails like warping or brittleness due to material limitations, which can lead to issues like bed adhesion problems, messy surfaces, or inconsistent extrusion, affecting your print's quality.

Conclusion

As you troubleshoot your 3D printing issues, keep in mind that identifying the root cause is crucial to resolving the problem. Whether it's bed adhesion, extrusion, or warping, each issue requires a specific solution.

By grasping the intricacies of 3D printing and following step-by-step guides, you'll be well on your way to producing high-quality prints.

With patience and persistence, you'll master the nuances of 3D printing and unleash the full potential of this groundbreaking technology.