While 3D printer nozzles share some standardized features, they are not entirely universal, and their compatibility varies greatly depending on the printer model, filament type, and specific printing requirements. You'll need to take into account factors like nozzle size, material, and wear resistance to select the right one for your needs. Different nozzles cater to specific printing requirements, including print speed, layer height, and filament type. When choosing a nozzle, think about your printing goals, budget, and the type of projects you'll be working on. As you delve into the world of 3D printing, you'll realize there's more to nozzles than meets the eye.

Nozzle Types and Materials

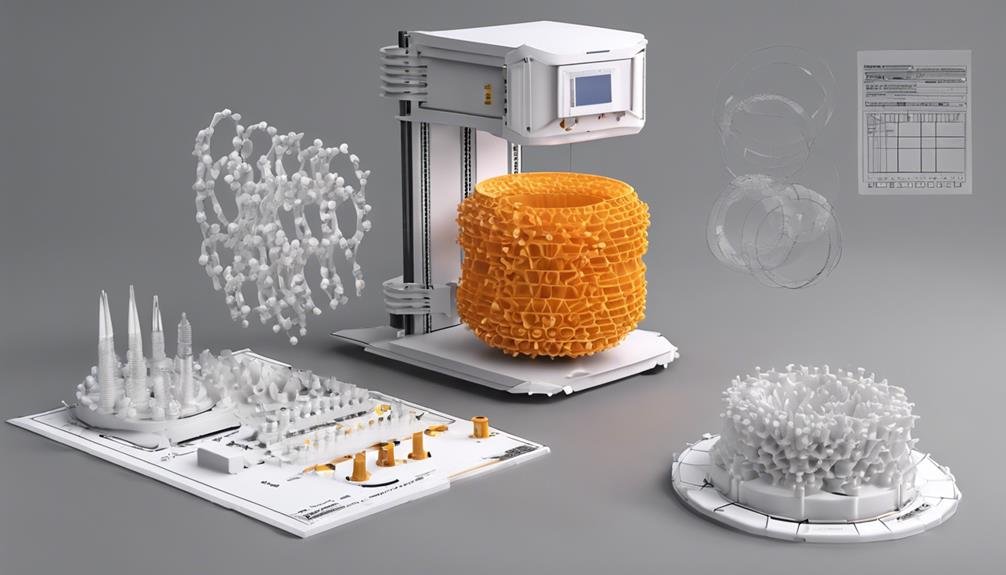

You'll find that 3D printer nozzles come in a variety of types, each made from distinct materials that cater to specific printing needs and filament types.

Printer Nozzles Universal, as the name suggests, are designed to be versatile, but they may not always be the best choice for every printing task. Brass nozzles, for instance, are a common and cost-effective option, suitable for most printing needs.

However, if you're working with abrasive filaments, you'll want to take into account hardened steel nozzles, designed specifically for their wear resistance. On the other hand, if you're looking for extreme wear resistance, ruby nozzles are the way to go.

The type of filament you're using also plays a significant role in selecting the right nozzle material. Different filaments require different nozzle materials to guarantee excellent printing results. By understanding the unique characteristics of each nozzle material, you can make informed decisions about which one to utilize for your specific printing needs.

Factors Affecting Nozzle Choice

As you navigate the complexities of 3D printing, it's clear that selecting the right nozzle involves more than just material choice, and several factors come into play when making your decision. Your printing experience greatly depends on considering these key factors to guarantee ideal results.

When choosing a nozzle, you'll need to think about the nozzle size, as it directly impacts layer height and overall print quality.

- Larger nozzles typically speed up prints, but may compromise on detail.

- Your filament type and required print speed will also influence your nozzle selection.

- Lastly, budget constraints will play a significant role in your decision-making process.

Taking these factors into account will vastly improve your printing experience, allowing you to achieve desired print quality and speed.

Nozzle Size and Compatibility

Choosing the correct nozzle size is vital, as it directly affects the level of detail, speed, and strength in your 3D prints.

You'll find that nozzle sizes vary from 0.1mm to 1.2mm, each suited for specific printing needs. Larger nozzles (0.4mm-1.2mm) are ideal for fast, high-flow printing, while smaller nozzles (0.1mm-0.3mm) provide greater detail and accuracy. However, compatibility is important – using an incompatible nozzle can damage your printer or result in poor print quality.

When selecting a nozzle, consider the material options, including brass, stainless steel, hardened steel, and even ruby for extreme wear resistance.

You'll also need to verify compatibility with your 3D printer model, filament diameter, and hot end settings. Different shapes and materials offer varying levels of durability and performance.

Changing and Maintaining Nozzles

Your 3D printer's nozzle is a consumable part that requires regular maintenance and occasional replacement to guarantee consistent print quality. As you print, the nozzle accumulates debris and residue, affecting layer heights and general print quality.

To prevent this, you should regularly clean and inspect your nozzle, checking for signs of wear and tear.

Here are some tips to maintain your nozzle:

- Clean your nozzle with a soft brush and gentle cleaning solution to remove debris and residue.

- Inspect your nozzle regularly for signs of wear, such as corrosion or blockages.

- Store spare nozzles in a clean, dry environment to prevent damage and ensure readiness for use.

Common Nozzle Sizes and Uses

Selecting the right nozzle size is crucial, since it directly impacts the print speed, detail resolution, and general quality of your 3D printing projects.

As you delve into the world of 3D printing, you'll come across different nozzle sizes, each suited for different printing requirements. Common nozzle sizes include 0.4mm, 0.6mm, and 0.8mm, each with its unique advantages.

For instance, larger nozzles like 0.8mm are ideal for faster prints with lower detail levels, making them perfect for printing large objects or prototypes. On the other hand, smaller nozzles such as 0.4mm are preferred for intricate and detailed prints, where precision is key.

When choosing a nozzle size, consider the layer thickness, thermal conductivity, and heater block design to ensure optimal printing performance.

Selecting the Right Nozzle

When you're preparing for a 3D printing project, you need to take into account the nozzle's compatibility with your filament of choice, as well as the desired print speed and layer height, to guarantee excellent printing results. Selecting the right nozzle is vital, as different nozzle types and sizes can greatly impact the printing process.

To guarantee top performance, consider the following key factors:

- Filament compatibility: Choose a nozzle that's designed for your specific filament type, whether it's PLA, ABS, or something else.

- Printing speed and layer height: Select a nozzle that can handle your desired print speed and layer height, ensuring smooth and accurate printing.

- Nozzle material and size: Decide on a nozzle material (brass, stainless steel, or hardened steel) and size (0.4mm nozzle, for example) that suits your printing needs.

Frequently Asked Questions

Do All 3D Printers Use the Same Nozzle?

You won't find a one-size-fits-all nozzle for all 3D printers due to varying thread diameters and sizes, which affect print quality and material limitations, making nozzle standards, printer interoperability, and hotend design critical considerations.

Does 3D Printer Nozzle Size Matter?

You'll find that nozzle size matters as it affects print quality, layer thickness, and material flow, ensuring a precise melt zone; a smaller nozzle provides finer details, while a larger one increases speed, so choose wisely for best results.

Are All Creality Nozzles the Same?

You'll find that not all Creality nozzles are the same, affecting print precision, as they vary in quality, durability, and hotend compatibility, with material variance impacting performance, so it's essential to choose the right one for your printer.

What Nozzles Are Compatible With Ender 3?

You can upgrade your Ender 3 with compatible nozzles like MK8 style, M6 thread, and 1.75mm filament diameter, allowing for printer modifications and nozzle swaps that fit your hotend design, ensuring Ender compatibility for best performance.

Conclusion

As you investigate the world of 3D printing, you'll find that nozzles are a vital component. While they may seem interchangeable, it's important to understand that each nozzle is designed for specific tasks and materials.

By considering factors like nozzle size, material, and compatibility, you'll be able to select the right nozzle for your project.

With proper maintenance and replacement, your nozzles will continue to deliver high-quality prints, ensuring your 3D printing experience is efficient and effective.