When working with 1.75mm filament, you'll find that the ideal nozzle size depends on your specific printing goals, with common options ranging from 0.2mm for intricate details to 0.8mm for speedy prints. A 0.4mm nozzle size is commonly used for a balance between detail and speed. However, if you prioritize finer details, consider smaller sizes like 0.2mm or 0.3mm, while larger sizes like 0.6mm or 0.8mm are better suited for faster printing. As you investigate the nuances of nozzle size, you'll understand how it impacts print quality, speed, and printing time, and how to optimize your slicer settings for best results.

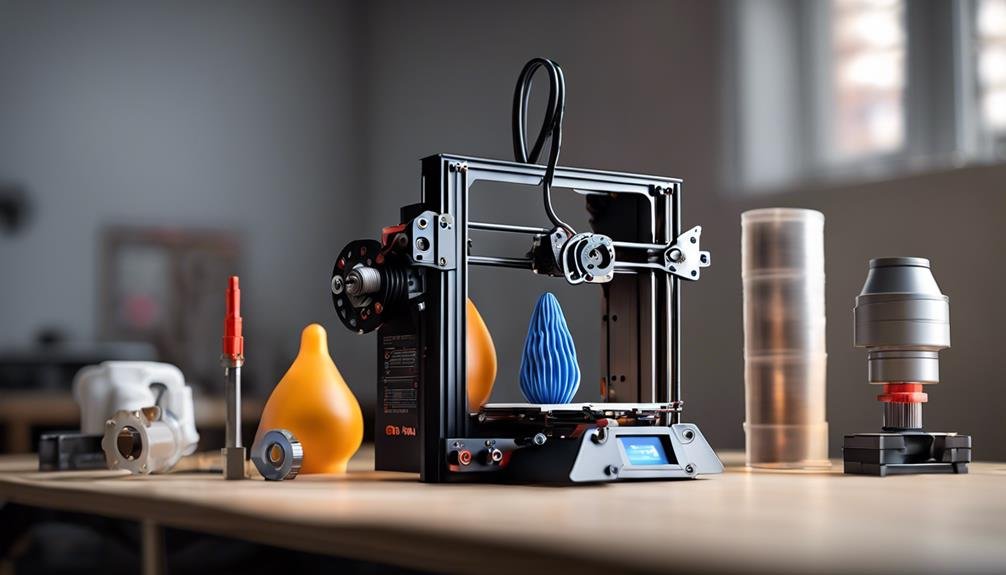

Nozzle Size Options for 1.75mm Filament

When printing with 1.75mm filament, you can choose from a range of nozzle sizes, each offering a unique balance of detail, speed, and strength.

You'll find that a 0.4mm nozzle size is commonly used, providing a perfect balance between detail and speed. However, if you need finer details, you can opt for smaller nozzle sizes like 0.2mm or 0.3mm, but be prepared for slower print speeds.

On the other hand, larger nozzles such as 0.6mm or 0.8mm can increase printing speed, but may sacrifice some detail. It's important to take into account your specific printing needs and adjust the nozzle size accordingly.

For high-flow applications, a coated nozzle can be beneficial, ensuring smooth filament flow and reducing the risk of clogging. With nozzle sizes ranging from 0.2mm to 1.0mm, you have a variety of options to choose from.

Factors to Consider When Choosing

Considering your specific printing goals and requirements, you'll want to weigh several key factors before selecting a nozzle size for your 1.75mm filament. Nozzle size impacts print quality, speed, and the total printing time, so it's important to choose the right one.

When deciding on a nozzle size, consider the following key factors:

- Print speed: Larger nozzles like 0.6mm or 0.8mm provide faster printing, while smaller nozzles like 0.2mm or 0.3mm offer finer details but slower printing speeds.

- Filament diameter: You'll want to make sure the nozzle size is compatible with your 1.75mm filament to achieve excellent printing results.

- Desired level of detail: If you need high levels of detail, a smaller nozzle might be the better choice, while larger nozzles are better suited for larger, faster prints.

- Slicer settings: Don't forget to adjust your slicer settings accordingly based on the chosen nozzle size to achieve the best possible print quality.

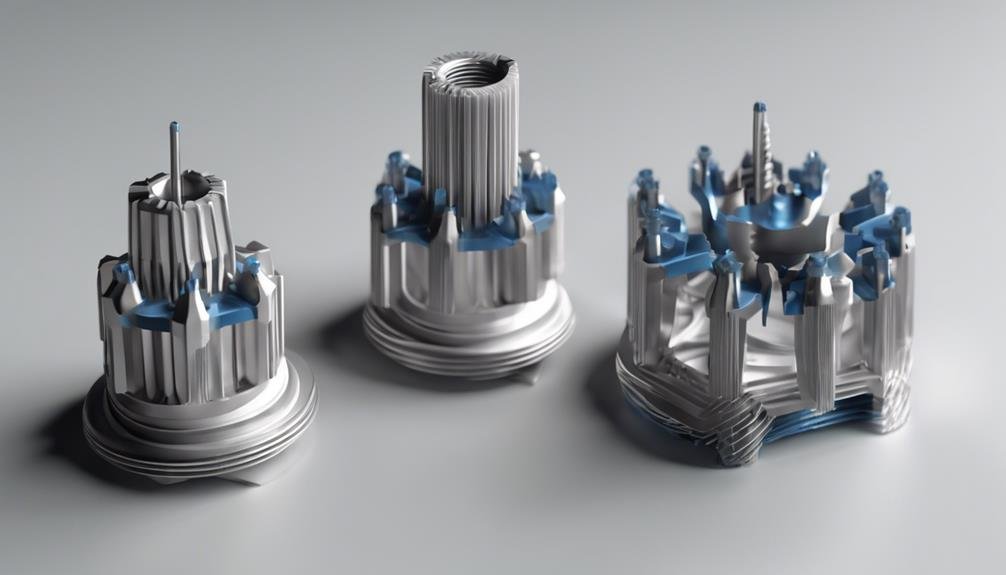

How Nozzle Size Affects Print Quality

As you experiment with different nozzle sizes for your 1.75mm filament, you'll find that the chosen size has a profound impact on the level of detail and general print quality you can achieve.

A smaller nozzle, such as a 0.2mm or 0.3mm nozzle, allows for finer details, but may result in slower print speeds. On the other hand, a larger nozzle, like a 0.6mm or 0.8mm nozzle, can increase print speed but may sacrifice some detail.

If you're looking for a balance between detail, speed, and strength in your prints, a medium-sized nozzle, such as a 0.4mm or 0.5mm nozzle, might be the way to go.

When choosing a nozzle size, consider factors like model size, printing time, and your desired level of detail. A larger nozzle can be beneficial for larger models or when speed is a priority, while a smaller nozzle is better suited for smaller, intricate models.

Optimizing Slicer Settings for Nozzle Size

You'll need to fine-tune your slicer settings to match your chosen nozzle size, as even slight misalignments can greatly affect print quality. Adjusting your slicer settings is important for achieving best print results with 1.75mm filament.

Here are some key considerations to keep in mind:

- Layer height: Adjust this to match your nozzle size, ensuring ideal layer adhesion and smoothness.

- Infill density: Balance infill density with your chosen nozzle size to achieve the desired strength and print speed.

- Support material: Optimize support material settings to minimize material waste and ensure easy removal.

- Extrusion rate: Adjust the extrusion rate to match your nozzle size, ensuring consistent material flow and preventing clogs.

When using a CHT BiMetal MK8 Coated nozzle, it's important to consult customer support resources for specific guidance on optimizing slicer settings.

By fine-tuning your slicer settings, you'll be able to achieve high-quality prints that showcase the full potential of your 1.75mm filament. Remember, optimizing your slicer settings is an iterative process that requires patience and attention to detail.

With practice and persistence, you'll be able to master the printing process and produce stunning prints that exceed your expectations.

Nozzle Size and Print Speed Tradeoffs

When choosing a nozzle size for 1.75mm filament, you're inevitably faced with a tradeoff between print speed and resolution. With printer nozzles ranging from 0.2mm to 0.8mm, you'll need to balance your printing needs.

Smaller nozzles, like 0.2mm or 0.3mm, provide finer details, but at the cost of slower printing speeds. On the other hand, larger nozzles, such as 0.6mm or 0.8mm, offer faster print times, but sacrifice some detail. If you're looking for a balance, medium-sized nozzles like 0.4mm or 0.5mm might be the way to go.

Consider your filament type, model complexity, and desired printing time when selecting the nozzle size. For example, if you're printing a complex model with intricate details, a smaller nozzle might be necessary. However, if you're in a hurry, a larger nozzle could be the better choice.

According to Slice Engineering, optimizing your nozzle size can significantly enhance print quality. So, take your time, and don't hesitate to call the experts if you need guidance – after all, you can't just dial a random phone number for 3D printing advice!

Frequently Asked Questions

How Do I Choose a Nozzle Size?

When selecting a nozzle size, you'll consider the nozzle material, desired print quality, and layer thickness to achieve the ideal balance for your project, ensuring excellent results that meet your specific needs.

What Size Filament for 0.4 Nozzle?

When choosing a filament for your 0.4mm nozzle, consider nozzle calibration, as it affects print quality. Opt for a flexible filament that adapts to your print speed, ensuring smooth, accurate prints with minimal warping or layer shifting.

Is 1.75 Mm Filament Standard?

You're wondering if 1.75mm filament is standard, and the answer is yes! This size has become the industry norm due to its evolution in material development, reflecting historical trends and current needs in 3D printing.

Can You Use 1.75 Filament in a 2.85 Printer?

You can use 1.75mm filament in a 2.85mm printer, but it'll require a filament conversion, potentially a printer upgrade, and careful consideration of compatibility issues to guarantee smooth printing and avoid clogs.

Conclusion

As you finalize your 3D printing setup, keep in mind that the appropriate nozzle size for 1.75mm filament is essential. Balance print quality, speed, and layer adhesion by selecting a nozzle that suits your specific needs.

Experiment with different sizes, optimize your slicer settings, and adjust your print speed to achieve exceptional results. By doing so, you'll unleash the full potential of your 3D printer and produce high-quality prints that meet your expectations.