You need to take into account ventilation when operating a 3D printer, as the printing process emits ultra-fine particles and volatile organic compounds that can negatively impact your health and the printing environment. Factors like filament type, printer technology, and workspace environment affect ventilation needs, with ABS and nylon emitting more particles than PLA. Inadequate ventilation can lead to health risks and printer performance issues. Explore enclosed printer designs, air purifiers, and DIY enclosures with fans or air hoses to improve air circulation and reduce risks. By understanding the importance of ventilation, you can create a safer and more effective 3D printing setup, and exploring further will help you find the best ventilation solution for your specific needs.

Understanding 3D Printer Emissions

When you fire up your 3D printer, it starts spewing out ultra-fine particles and volatile organic compounds (VOCs) that can pose health risks if not handled properly. During printing, your printer releases these harmful emissions into the air, which can lead to respiratory issues and other health problems.

The type of filament used can impact the amount of emissions released, with ABS and nylon filaments emitting higher concentrations of UFPs and VOCs compared to PLA. To minimize health risks, it's important to take precautions when operating your 3D printer. Utilizing personal protective equipment and operating in clean, dust-free areas is crucial.

Additionally, ensuring good ventilation in your printing area is important to mitigating the risks associated with 3D printing emissions. Operating your printer in a well-ventilated area, such as an ASHRAE-certified room, can help reduce the risks.

Factors Affecting Ventilation Needs

Your ventilation needs depend on several key factors, including the type of filament you're using, the printer technology, and the workspace environment.

For instance, if you're working with PLA, your ventilation requirements might be less stringent compared to ABS, which emits higher concentrations of UFPs and VOCs.

The type of printer technology you're using also plays a role, as SLA and FDM printers produce ultrafine particles, VOCs, and styrene, which necessitate proper ventilation.

The workspace environment is another critical factor, as enclosed spaces lack proper ventilation outlets, requiring additional measures for fume extraction. On the other hand, open spaces allow for natural air circulation, potentially reducing the need for extensive ventilation setups.

When determining your ventilation solutions, consider the location of your workspace and the duration of your printing projects, which typically run for 5-7 hours. By taking these factors into account, you can ensure you're providing adequate air changes and minimizing the risks associated with 3D printing emissions.

This will ultimately lead to a safer and healthier printing environment.

Risks of Inadequate Ventilation

Failing to provide adequate ventilation in your 3D printing workspace can expose you to a range of health risks, from respiratory problems and skin irritation to headaches and dizziness. When you're working with 3D printers, you're dealing with printer fumes that contain Volatile Organic Compounds (VOCs), which can accumulate in the air if not properly ventilated. Prolonged exposure to these fumes can cause discomforts like headaches and dizziness, and even lead to more severe health issues over time.

In addition to the health risks, inadequate ventilation can also impact your printer's performance and lifespan. A poorly ventilated workspace can lead to clogged print nozzles, faulty temperature control, and other issues that can reduce the quality of your prints.

Ventilation Options for 3D Printers

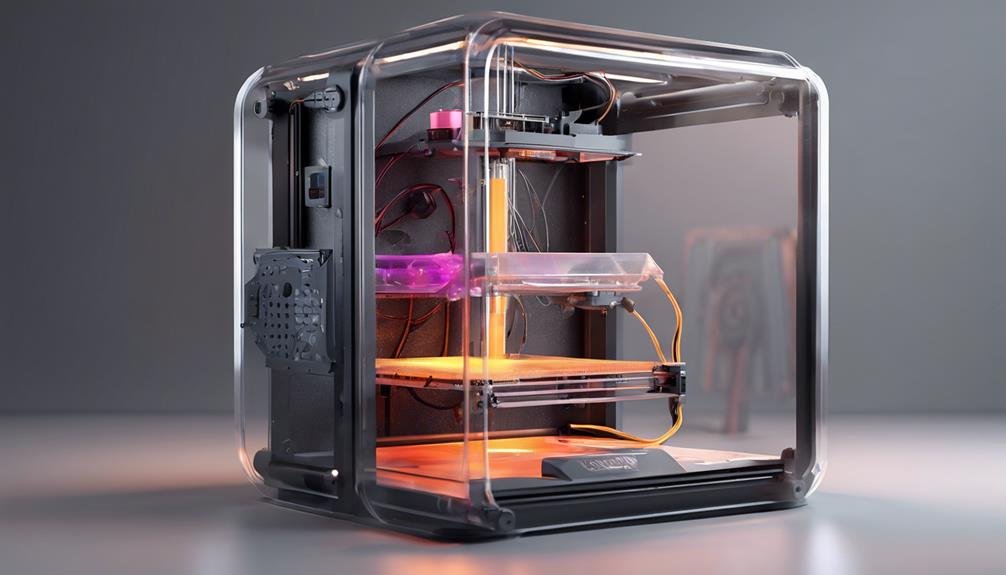

To minimize health risks and maintain a safe working environment, you can consider different ventilation options for your 3D printer. These options include enclosed printer designs, natural ventilation, air purifiers, and DIY printer enclosures with proper ventilation or air extractors.

When choosing an air purifier, look for one equipped with a HEPA filter. This type of filter can effectively remove pollutants and VOCs from the air, which can be particularly crucial if you're printing with materials that emit strong fumes. Natural ventilation through windows or doors can also help disperse fumes and maintain air quality.

However, if you're working in a small, enclosed space, you may need to rely on other ventilation options. Building a DIY printer enclosure with proper ventilation or air extractors can improve air circulation and reduce the concentration of harmful particles.

DIY Enclosure Ventilation Solutions

By incorporating ventilation solutions into your DIY enclosure, you can create a safer and more comfortable printing environment. One effective way to achieve this is by adding air hoses or fans to your DIY enclosure, which helps maintain air quality by dispersing harmful particles and VOCs produced during the printing process.

Without proper ventilation, enclosed 3D printers can lead to overheating concerns, particularly when working with materials like resin. To prevent this, you can position your 3D printer near a window or utilize an exhaust fan to improve air circulation.

Another option is to install a fume hood, which can aid in ventilation and prevent the buildup of fumes in enclosed spaces. By implementing these ventilation solutions, you can establish a secure and comfortable working environment, free from the risks associated with poor air quality.

Air Purifiers for 3D Printing

You can greatly improve the air quality in your 3D printing space by incorporating an air purifier with a HEPA filter, which captures ultrafine particles and VOCs emitted during the printing process. These filters can capture particles as small as 0.3 microns, greatly improving the air quality in your printing environment.

Moreover, many air purifiers also feature activated carbon filters, which can effectively trap and remove volatile organic compounds generated by 3D printers. By investing in an air purifier, you can complement your existing ventilation strategies, especially in enclosed spaces where natural air circulation is limited. This added layer of protection can boost safety and air quality during 3D printing processes.

When selecting an air purifier, look for one that combines a HEPA filter with an activated carbon filter for maximum effectiveness. By doing so, you can create a safer and healthier environment for yourself and others working in the printing space.

Workspace Considerations for Ventilation

When establishing your 3D printing workspace, it's important to take into account the physical space itself, as the layout and design can greatly impact ventilation. You'll want to think about the type of space you're working in – enclosed or open – as this will directly affect your ventilation requirements.

Enclosed spaces, for instance, can lead to fume buildup from the 3D printing process, making it vital to prioritize ventilation. On the other hand, open spaces allow for natural air circulation, reducing the concentration of harmful particles.

If you're working with PLA filament, your ventilation requirements might be less stringent, but it's still crucial to ensure proper airflow. As you set up your workspace, keep in mind that the 3D printing process produces ultrafine particles, VOCs, and styrene, which can be hazardous to your health.

Implementing Effective Ventilation Strategies

Two effective ventilation strategies you should consider implementing in your 3D printing workspace are natural airflow and exhaust fans.

Natural airflow involves placing your printer near an open window or using a ventilation system that allows fresh air to circulate in and out of the room.

On the other hand, exhaust fans can be installed above your printer to directly remove fumes and particles from the printing process.

When it comes to implementing these strategies, consider the following:

- Use a Creality Ender or other enclosed printers with built-in ventilation systems to reduce UFPs and VOCs.

- Install carbon filters in your ventilation system to absorb and neutralize harmful particles and fumes.

- Ensure good airflow by keeping your workspace clutter-free and avoiding obstacles that may block air circulation.

- Consider using air purifiers as an additional measure to remove airborne pollutants.

- Regularly clean and maintain your ventilation system to guarantee optimal performance.

Frequently Asked Questions

Is It Safe to Have a 3D Printer in Your House?

When you bring a 3D printer into your home, you're not just adding a new decor piece, you're also potentially affecting your family's safety and air quality.

Do 3D Printers Give off Toxic Fumes?

When you use your 3D printer, you're exposed to toxic fumes from chemical reactions between printing materials and heat, affecting air quality and posing health risks through fume exposure, especially with ABS and nylon filaments.

Is It Safe to Sit in a Room With a 3D Printer?

When you sit in a room with a 3D printer, you're exposed to air quality concerns; however, using room circulation systems, strategic printer placement, and minimizing noise level impact can make it safer for you to be in the same room.

Is PLA Safe to Print Without Ventilation?

You're wondering if PLA is safe to print without ventilation. Fortunately, PLA's low particle emissions and minimal VOCs make it a relatively safe choice, even without ventilation systems, under typical printing conditions, thanks to its unique material properties.

Conclusion

As you've learned, 3D printing can release harmful particles and fumes, making ventilation essential. By understanding the factors affecting ventilation needs, you can implement effective strategies to minimize risks.

From DIY enclosure ventilation solutions to air purifiers, you have options to create a safer printing environment. Consider your workspace, choose the right ventilation method, and prioritize your health and safety.

By doing so, you'll be well on your way to enjoying a healthier, more productive 3D printing experience.

Contents

- 1 Understanding 3D Printer Emissions

- 2 Factors Affecting Ventilation Needs

- 3 Risks of Inadequate Ventilation

- 4 Ventilation Options for 3D Printers

- 5 DIY Enclosure Ventilation Solutions

- 6 Air Purifiers for 3D Printing

- 7 Workspace Considerations for Ventilation

- 8 Implementing Effective Ventilation Strategies

- 9 Frequently Asked Questions

- 10 Conclusion