Your 3D printer's lifespan depends on several factors, including the quality of its components, how well you maintain it, and the frequency of its use. Industrial-grade printers, for instance, can last considerably longer than their hobbyist counterparts. Regular maintenance tasks, such as cleaning and calibration, can prevent printer failure and extend its life. Environmental conditions, like temperature and humidity, also play an important role in determining your printer's longevity. By balancing print frequency with maintenance and adopting proactive steps, you can guarantee your printer remains reliable and efficient. Now, let's take a closer look at the specifics that will help you get the most out of your 3D printer.

Factors Affecting 3D Printer Longevity

Your 3D printer's lifespan is heavily influenced by a combination of factors, including how frequently you use it, the quality of its components, and how well you maintain it.

The quality of components, particularly Electronic Components, plays a significant role in determining Printer Life. Industrial-grade 3D printers, for instance, tend to last longer due to their robust construction and higher quality components.

Regular maintenance is also vital in extending the lifespan of your printer. Performing regular maintenance tasks, such as cleaning and replacing spare parts, can help prevent Causes of 3D Printer failure.

Operating the printer in ideal environmental conditions is also important, as extreme temperatures and humidity can affect its performance. By understanding these factors, you can take proactive steps to ensure your printer remains reliable and functional over time.

Impact of Rapid Technological Advancements

When investing in a 3D printer, it's important to consider the rapid pace of technological advancements in the field, which can make your device outdated in just a few years. Technology advances at an incredible rate, and what's cutting-edge today might be obsolete tomorrow.

New features and capabilities in newer models may outpace the functionality of older printers, rendering them less desirable. Additionally, compatibility issues with software updates and materials can affect the longevity of 3D printers, requiring you to upgrade components or firmware to keep up with evolving technologies.

To optimize the lifespan of your 3D printer, it's vital to stay informed about the latest developments and be prepared to adapt to changes. By understanding the pace of technological progress, you can make informed decisions about upgrading or replacing your printer, ensuring you stay at the forefront of 3D printing innovation.

Print Frequency and Printer Wear

As you crank out print after print, you're likely to notice the toll it takes on your 3D printer's components, and it's crucial to recognize the impact of print frequency on printer wear.

The more you print, the more wear and tear your printer's parts and components will undergo. Continuous printing sessions without proper cool-down periods can accelerate the degradation of printer parts, reducing their lifespan.

Regularly printing large and complex models can strain the printer's mechanisms, causing mechanical parts to wear out faster. High-volume printing can cause belts, nozzles, and other moving parts to wear out faster, affecting printer performance.

However, balancing print frequency with regular maintenance can help extend the longevity of a 3D printer. By acknowledging the impact of print frequency on printer wear, you can take proactive steps to maintain your printer's components, ensuring peak performance and extending its lifespan.

The Role of Maintenance in Longevity

Proper maintenance is essential to extending the lifespan of your 3D printer, and it starts with adopting a routine that includes regular cleaning, lubrication, and part replacements. By doing so, you'll be able to prevent breakdowns and maintain consistent printing quality over time. Neglecting maintenance can lead to premature wear on critical components, resulting in more frequent breakdowns and a shorter printer lifespan.

On the other hand, investing time and effort into regular maintenance can optimize the return on investment and overall performance of your 3D printer. Tailoring your maintenance routine to your specific printer model can address common issues and increase longevity. By staying on top of maintenance, you'll be able to extend the lifespan of your printer and maintain high-quality print quality.

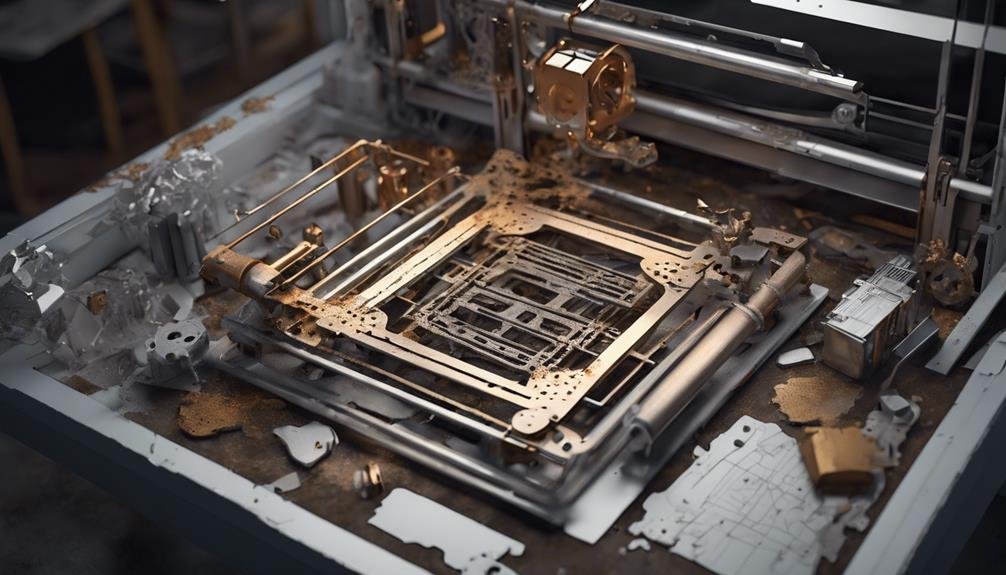

Common Causes of 3D Printer Breakdowns

Identify and address the root causes of breakdowns, and you'll be well on your way to minimizing downtime and maximizing your 3D printer's lifespan. Printer breakdowns can be frustrating and costly, but understanding common causes can help you prevent them. Mechanical parts, such as belts and nozzles, are prone to wear and tear, affecting print precision and reliability. Electronic components, like motors and control boards, can malfunction, leading to operational issues and print failures.

| Causes of Breakdowns | Effects on Printer |

|---|---|

| Wear and tear on mechanical parts | Decreased print precision, reduced reliability |

| Malfunctioning electronic components | Operational issues, print failures |

| Environmental factors (dust, humidity, temperature) | Impaired printer functionality, performance |

| Poor maintenance, neglect | Reduced printer lifespan, frequent breakdowns |

Maximizing Printer Lifespan Strategies

By implementing a few key strategies, you can greatly extend the lifespan of your 3D printer and guarantee peak performance over time. Regular maintenance is important, as it prevents clogs and maintains the printer's components in good condition.

Using high-quality filament from reputable brands reduces the risk of clogging and ensures consistent print quality. Calibrating the printer regularly improves accuracy and minimizes misprints during the printing process.

Strategic upgrades, such as replacing worn-out components or upgrading the hotend or cooling system, can greatly improve the printer's efficiency and longevity. Investing in spare parts and staying informed about market trends can also help optimize the lifespan of your 3D printer.

Choosing Quality Filament Matters

You can further protect your 3D printer's longevity by selecting high-quality filament that reduces the risk of clogs, print failures, and nozzle blockages. By choosing quality filament, you're ensuring a smoother printing experience and extending the life of your printer.

Reputable filament brands minimize the risk of print failures and nozzle blockages, which can lead to costly repairs or even render your printer useless. Investing in good filament can reduce wear on components, such as the nozzle and extruder, which are prone to damage from low-quality materials.

High-quality components, including the filament, are vital for maintaining excellent print quality and durability. Print durability, strength, and finish are all impacted by filament quality, making it a significant factor in maximizing your printer's lifespan.

Upgrade Paths for Extended Life

As you capitalize on your 3D printer's potential, strategic upgrades can breathe new life into the machine, greatly extending its lifespan. By upgrading components used, such as hotends, extruders, and control boards, you can notably improve performance and longevity. Investing in quality replacement parts guarantees that your printer remains reliable and efficient. Additionally, software updates and firmware upgrades provide enhanced features and compatibility for older models, keeping your printer up-to-date with advancements in 3D printing technology.

| Upgrade Path | Benefits |

|---|---|

| Hotend Upgrades | Improved print quality, reduced maintenance |

| Extruder Upgrades | Enhanced material handling, increased precision |

| Control Board Upgrades | Improved connectivity, enhanced firmware support |

Signs Your 3D Printer Needs Replacement

Your 3D printer's declining performance and recurring issues may suggest that it's time to contemplate replacing it, rather than persisting in investing in upgrades and repairs. If you're experiencing frequent printer breakdowns, or the print quality has deteriorated greatly, it might be a sign that your printer is nearing the end of its lifespan.

Here are some signs that may indicate the need for a replacement:

- Reduced print quality: Layer inconsistencies, warping, or other issues that affect the general print quality may suggest that your printer is no longer capable of producing satisfactory results.

- Frequent malfunctions: If your printer is often breaking down, it may be a sign that it's time to think about replacing it with a more reliable model.

- Outdated technology: If your printer is using obsolete technology, it may lead to compatibility issues with software and materials, making it difficult to use.

- Difficulty finding replacement parts: If you're struggling to find replacement parts or if the manufacturer is no longer providing support, it may be time to think about a new printer.

- Cost of repairs: If the cost of repairs exceeds the value of the printer or investing in upgrades becomes impractical, it's likely time to think about a replacement.

Assessing Printer Performance Over Time

Regular monitoring of your 3D printer's performance over time is crucial to identify subtle changes in print quality and address potential issues before they escalate.

You can do this by regularly checking layer height consistency, as any deviations can affect print quality.

Evaluate dimensional accuracy, surface finish, and overhang capability to assess print quality.

Conduct calibration tests for nozzle temperature, bed leveling, and filament diameter to maintain print reliability.

Analyze print quality indicators over time to guarantee consistent results.

Furthermore, monitor performance metrics to identify any changes in printer functionality.

By doing so, you can pinpoint potential issues before they lead to printer breakdowns, reducing downtime and extending your printer's lifespan.

Consistent performance and routine maintenance are key to maximizing your printer's lifespan.

Frequently Asked Questions

Is It Okay to Run a 3D Printer for 24 Hours?

You can safely run your 3D printer for 24 hours with continuous operation, thanks to long-lasting parts, ensuring non-stop printing, endless printing, and marathon printing, as long as you monitor it for issues and maintain printer durability.

Do 3D Printers Require a Lot of Maintenance?

You'll find that 3D printers do require regular maintenance to run smoothly, involving regular cleaning, scheduled checks, and preventive steps to optimize performance and extend the lifespan of wearable parts, ensuring timely replacement cycles and calibration needs are met.

How Long Does a 3D Printer Extruder Last?

You'll typically get 800 to 2,000 printing hours from your 3D printer's extruder, depending on factors like filament quality, printing frequency, and extruder calibration, in addition to your diligence with cleaning and maintenance to prevent material wear and nozzle corrosion.

How Long Does a 3D Printer Bed Last?

You'll get thousands of hours from your 3D printer bed, but it's essential to maintain it properly; guarantee accurate bed calibration, monitor print quality, and watch for wear patterns, adhesion issues, and thermal stress affecting the surface finish.

Conclusion

As you think about the lifespan of your 3D printer, keep in mind that regular maintenance, quality filament, and moderate print frequency are essential for extending its life.

Be mindful of signs of wear, such as clogged nozzles or faulty motors, and stay up-to-date with upgrades and replacements.

By doing so, you can optimize your printer's performance and longevity, ensuring you get the most out of your investment.

Contents

- 1 Factors Affecting 3D Printer Longevity

- 2 Impact of Rapid Technological Advancements

- 3 Print Frequency and Printer Wear

- 4 The Role of Maintenance in Longevity

- 5 Common Causes of 3D Printer Breakdowns

- 6 Maximizing Printer Lifespan Strategies

- 7 Choosing Quality Filament Matters

- 8 Upgrade Paths for Extended Life

- 9 Signs Your 3D Printer Needs Replacement

- 10 Assessing Printer Performance Over Time

- 11 Frequently Asked Questions

- 12 Conclusion