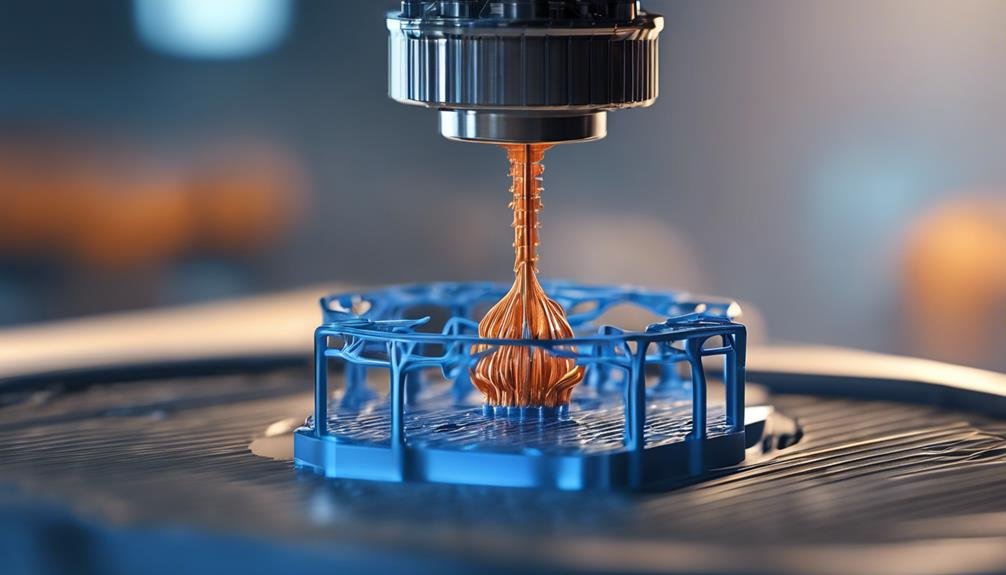

When you're evaluating the precision of 3D printers, you'll find that factors like resolution, evaluation, uncover, investigate, vital, evaluating. Different technologies, such as FDM, SLA, and SLS, offer varying levels of precision, ranging from ±0.5 mm to ±0.05 mm. Material selection is also important, as some materials provide higher accuracy than others. To achieve high-precision prints, you'll need to optimize printer resolution and calibration, select materials that match your project requirements, and consider tradeoffs in speed or design modifications. As you investigate the intricacies of 3D printing, you'll uncover how to balance these factors to achieve precise prints.

Factors Affecting 3D Printer Precision

Achieving precision in 3D printing requires taking into account a multitude of factors that can either make or break the accuracy of your printed parts. You need to take into consideration the resolution, calibration, and mechanical stability of your 3D printer, as these key factors have a substantial impact on the precision of your prints.

Material properties, design considerations, and machine hardware capabilities also play a vital role in determining the accuracy of your prints. Additionally, environmental conditions like temperature and humidity can affect the precision of your 3D printed parts.

To achieve high levels of precision, you must select a 3D printer with the right material capabilities, speed, and precision level for your specific application. Additive manufacturing technologies, such as SLS and MJF, offer high precision and accuracy, making them ideal for demanding applications.

3D Printing Technologies Compared

In the domain of 3D printing, you have a variety of technologies to choose from, each with its own strengths and precision levels that cater to specific applications and design requirements.

When it pertains to accuracy, Fused Deposition Modeling (FDM) technology offers a relatively essential precision of approximately ± 0.5 mm, making it suitable for cost-effective prototyping.

On the other hand, Stereolithography (SLA) 3D printing provides precision with tolerances around ± 0.1 mm, ideal for detailed and intricate designs.

Selective Laser Sintering (SLS) achieves accuracy of about ± 0.3 mm, allowing for high-quality functional parts and complex geometries.

Multi Jet Fusion (MJF) technology guarantees accuracy through accurate binding of powder layers, offering ± 0.1 mm precision for production-grade parts.

Ultimately, Material Jetting technology boasts precision levels as fine as ± 0.05 mm, making it suitable for high-detail applications and intricate models.

Understanding the strengths and weaknesses of each 3D printing technology is essential in achieving top-notch dimensional accuracy and precision in your printing processes.

Measuring Dimensional Accuracy

When evaluating a 3D printer's performance, you need to take into account parameters like dimensional tolerance to accurately assess its precision. Dimensional accuracy is a critical aspect of measuring precision in 3D printing, as it directly affects the accuracy of parts produced. The printing process can be prone to warping or shrinkage, which can greatly impact the dimensional accuracy of printed parts. Moreover, the need for support structures can affect the surface accuracy and general precision of 3D printed objects.

To provide a better understanding of the importance of dimensional accuracy, here is a comparison of the expected dimensional accuracy of different 3D printing technologies:

| Technology | Dimensional Accuracy |

|---|---|

| FDM | ±0.1-0.3 mm |

| SLA | ±0.01-0.05 mm |

| SLS | ±0.1-0.3 mm |

| Binder Jetting | ±0.1-0.3 mm |

| DLP | ±0.01-0.05 mm |

Design considerations play a significant role in minimizing issues like warping or shrinkage that can affect dimensional accuracy. By understanding the importance of dimensional accuracy and the factors that affect it, you can optimize your 3D printing process to produce parts with high precision and accuracy.

Materials and Their Precision

As you optimize your 3D printing process for precision, you'll find that the material you choose plays a substantial role in achieving the desired level of accuracy. Material properties greatly influence the dimensional accuracy of 3D printed parts. For instance, some materials may improve certain properties at the cost of precision in 3D printing.

When it comes to precision, not all materials are created equal. Here are three examples of materials that offer varying levels of precision:

- SLA Resin: Known for its high dimensional accuracy, SLA resin is a popular choice for applications where precision is paramount.

- Nylon: As an industrial-grade material, Nylon provides a balance of strength and precision, making it suitable for a wide range of 3D printing applications.

- Ultem: This high-precision material offers advanced accuracy capabilities, but at a higher cost due to its advanced material properties.

High-precision materials often come at a higher cost due to their advanced accuracy capabilities. However, using industrial-grade materials like Nylon and Ultem can provide a balance of strength and precision, making them suitable for a wide range of 3D printing applications.

Achieving High Precision Prints

You can achieve high precision prints by optimizing your 3D printer's resolution, calibrating it regularly, and carefully selecting materials that match your project's requirements. To guarantee high precision, it's crucial to take into account the interplay between resolution, material properties, and design considerations.

For instance, a high-resolution print may not be achievable with certain materials, requiring tradeoffs in speed or design modifications. Moreover, you should also factor in the hardware capabilities of your 3D printer, along with environmental conditions that may impact print quality.

By carefully balancing these factors, you can produce parts that meet stringent design specifications and display precise dimensions and surface finishes. This level of precision is vital for creating functional prototypes and end-use parts.

Precision in Real-World Applications

In aerospace, automotive, and healthcare, where precision is paramount, 3D printing technologies are being utilized to produce critical components with exacting tolerances. Industrial-grade 3D printers are capable of achieving high precision levels, reaching accuracies as tight as ±0.05 mm for intricate parts. This level of precision is essential for producing functional prototypes and end-use parts that meet the exacting standards of these industries.

Here are some key applications where precision 3D printing technologies like SLA, SLS, and MJF are making a significant impact:

- Aerospace: Producing lightweight, complex components with tight tolerances for aircraft and spacecraft.

- Automotive: Creating functional prototypes and end-use parts, such as engine components and interior trim, with high accuracy.

- Healthcare: Manufacturing custom implants, surgical guides, and medical devices with exacting precision.

In these industries, precision is paramount, and 3D printing technologies are rising to the challenge. By achieving high levels of accuracy, these technologies are enabling the production of critical components that meet the exacting standards of these industries.

Frequently Asked Questions

How Are 3D Printers so Precise?

You achieve precise prints thanks to micro movement control, laser-guided systems, and stepper motor accuracy, which work in tandem with advanced algorithms, high-resolution sensors, and precision nozzles to guarantee nanoscale tolerances in your final product.

What Type of 3D Printer Is Most Precise?

You're looking for the most precise 3D printer type – it's likely a resin-based SLA or DLP printer, offering high-resolution layers as thin as 25-100 microns, or a Polyjet printer with 16-micron layers, ideal for intricate details and smooth surfaces.

Why Is My 3D Print Not Precise?

You're wondering why your 3D print isn't precise? Check for layer shifting, temperature fluctuations, warped beds, inconsistent filament, poor calibration, clogged nozzles, low-quality models, incorrect settings, human error, or material limitations – one of these culprits is likely causing the issue.

What Is a Good Dimensional Accuracy for a 3D Printer?

You're looking for a good dimensional accuracy for your 3D printer, which depends on factors like laser calibration, micrometer tolerance, surface roughness, material shrinkage, thermal expansion, and printer maintenance. It is important to regularly check and calibrate your printer to ensure that it maintains the necessary dimensional accuracy. Additionally, considering the material shrinkage and thermal expansion of the filament you are using is crucial in achieving precise 3D prints. Another important factor to consider is the surface roughness, which can affect the overall quality of the printed object. When comparing 3d printer filament prices, it’s also important to take into account the quality and consistency of the material, as well as any potential impact on dimensional accuracy.

Conclusion

As you venture into the world of 3D printing, you'll find that precision is paramount. By understanding the factors that affect printer accuracy, comparing technologies, and measuring dimensional accuracy, you'll be well-equipped to achieve high-precision prints.

With the right materials and techniques, you can unleash the full potential of 3D printing, from prototyping to production. Now, put your knowledge into practice and create prints that meet your exacting standards.